New Cantilever Laser Welding Machine for Mold Repairing

New Cantilever Laser Welding Machine for Mold Repairing

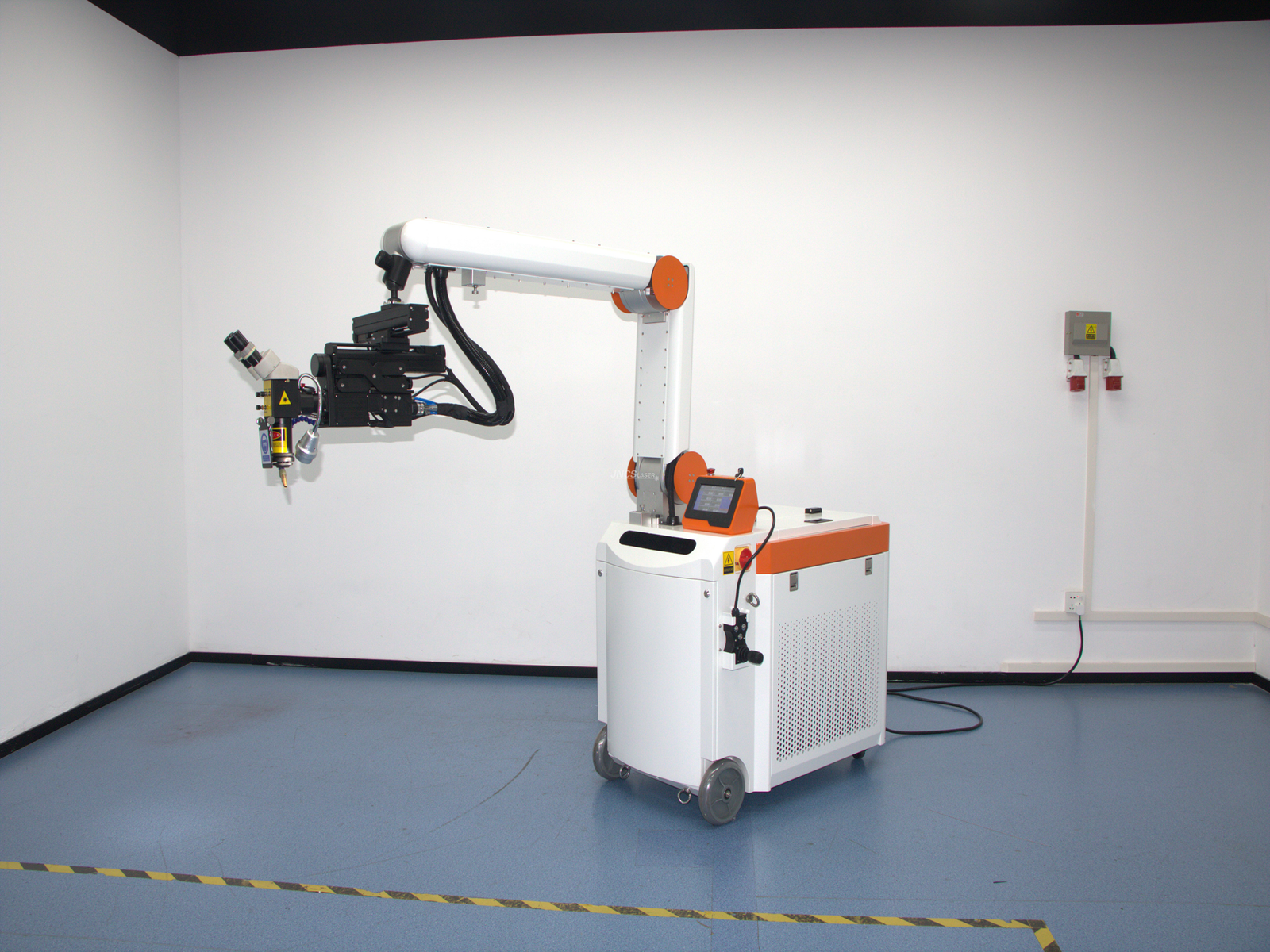

The QCW (Quasi-Continuous Wave) 300W Fiber Laser Welding Machine with a Big Crane is specifically designed for heavy-duty and precision welding applications, particularly suited for industries like mold repairing, automotive manufacturing, and large-scale metal fabrication. The addition of a big crane provides flexibility to handle large or difficult-to-move workpieces, improving efficiency and precision in various tasks.

Main Feature:

- 1. Adopt QCW laser; the light spot is stable and energy-saving.

Compared with traditional welding machines, there is no need to replace consumables

2. Equipped with a dedicated chiller, which can meet long-term welding and provide better stability;

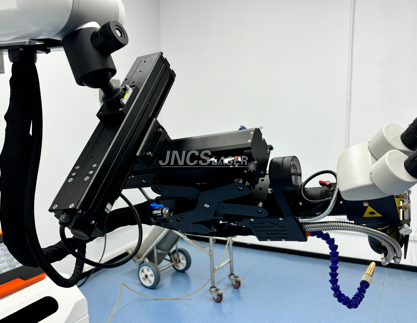

3. Equipped with a three-dimensional load-bearing workbench base with electric lifting, the workbench moves using precision ball screws and high- precision straight guide rails, which are light and flexible, with precise

positioning and a load-bearing capacity of up to 100 kg;

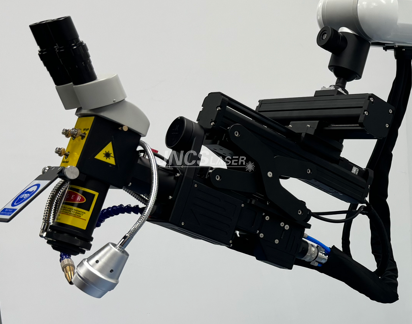

4. The laser head can be easily rotated 180 degrees, making it convenient to repair welding on any side;

5. Equipped with a gas protection system, which effectively protects the

product from argon gas protection during the welding process, maintains the

product’s true color and ensures welding quality.

Machine Configurations:

QCW Quasi-Continuous Wave High precision, high quality ,Suitable for applications requiring precision and fine welding, especially for intricate or detailed work, and for situations where thermal distortion must be minimized.

X 150mm Y 150mm Z 100mm

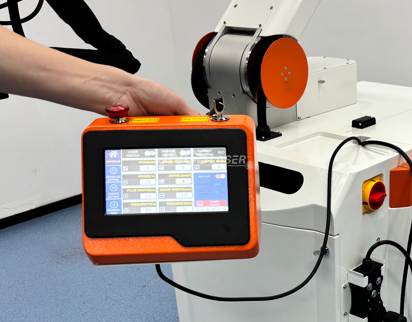

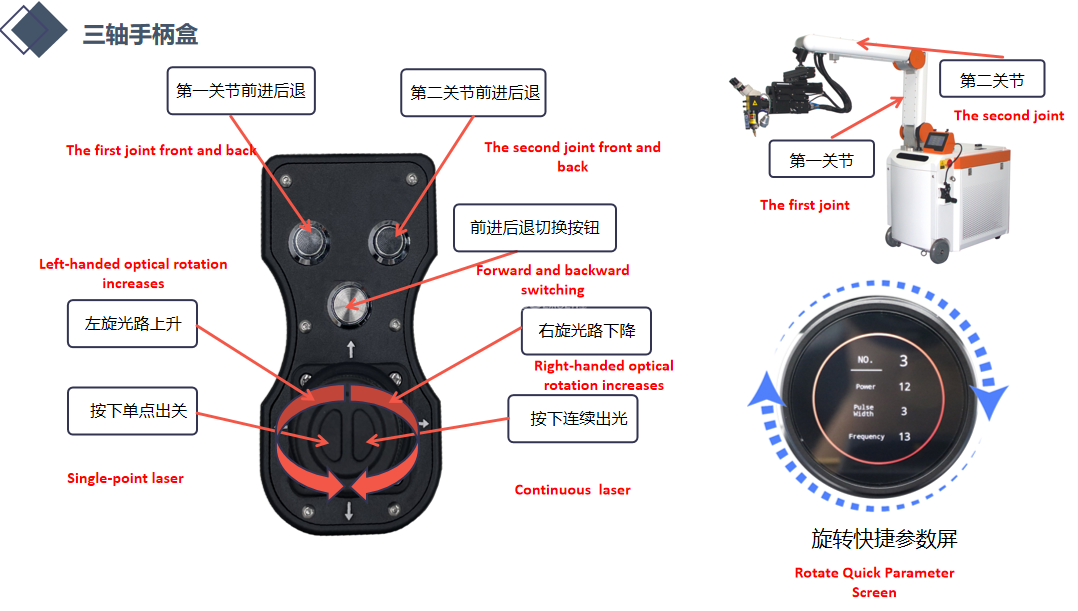

Support multi language We can change power, pulse width, frequency etc.

Adjust welding Angle and position flexibly, For large molds, molds can be welded directly on the ground or forklift without working table. Arm length: 1600mm Arm height : 1500mm

The welding head can be adjusted up and down 90 degree, left and right rotate angle 360 degree.

High configuration digital display water chiller, Good cooling effect, good heat dissipation

Machine Parameters:

Model | CS-150W-XB CS-300W-XB CS-F1500W |

Rated Laser Power | 150W 300W 1500W |

Laser type | QCW QCW CW |

The laser wavelength, | 1064nm |

Maximum regulation frequency | 1-30Hz 1-30Hz 1-25Hz |

Pulse Width | 1-20Ms 1-20Ms 1-60Ms |

Light spot adjustment range | 0.2-3mm (150W) 0.2-5mm (300W 1500W) |

Aiming and positioning | Microscope (optional camera system) |

Fiber line length | 10m |

Chiller cooling power | 0.46 0.6 CW1500 |

Rated Power | 2.5kw 3kw 7kw |

Cooling way | Water cooling |

Demand for electricity | AC220V 1 phase 50HZ 60A |

Package Size and Gross Weight | 154*82*142cm 355kg |

Video Tutorials & Instructional Video:

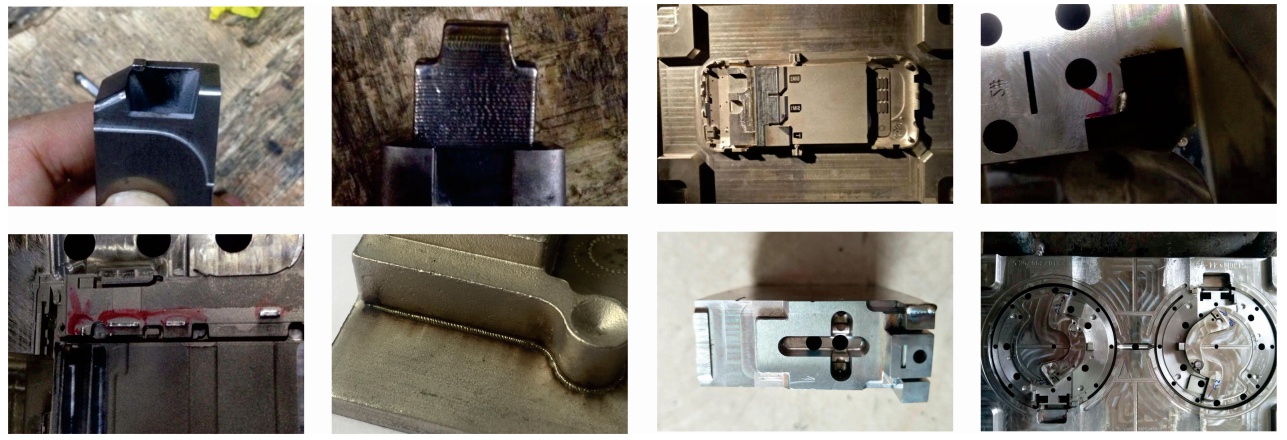

Sample Display:

Suitable for large mold repair welding, mobile phone communications, jewelry crafts, electronic components, clocks, sensors, precision machinery, hardware, gas and vehicle parts, etc., various metals and alloys.

How to Play Order:

- Will you please inform us the below information?

- What material will you weld?

- Will you please share with us your sample photos?

- We would like to recommend you suitable laser welding machine accordingly and offer you our best price.

- Will you ship machine by sea, by air ? So, please tell us your nearest sea por, air port. We would like to check freight fee for you.

- After you confirm machine model, power, price, freight fee, then please inform us your Consignee Information ( company name, address, contact, phone number ) we will make Proforma Invoice for you to play order.

- You can remit the payment according to Proforma Invoice.

- Machine will be ready 10-15 working days after your payment.

- We will share with you machine photos and videos since machine is ready.

- After confiming all is fine, we will book shipment.

- We will share with you bill of lading, commercial invoice, packing list after shipment.

- You can operate laser welding machine according to user video and user manual.

- If any questions about using, we would like to guide you online.

CN

CN AR

AR ES

ES RU

RU