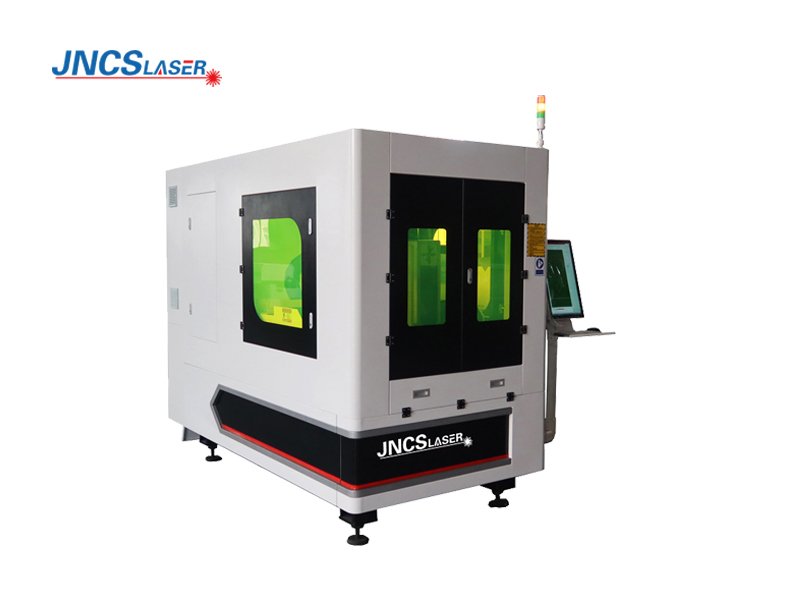

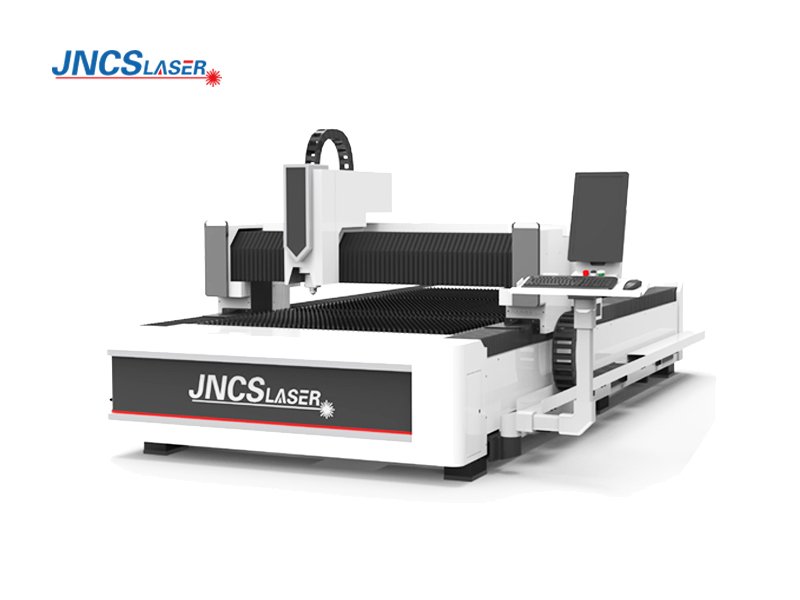

Fiber Laser Stainless Steel Cutting

Fiber laser cutting machines are highly effective for cutting stainless steel due to their precision, efficiency, and ability to handle various thicknesses. Here’s an overview of the features, benefits, and applications of fiber laser cutting for stainless steel:

Key Features:

High Precision Cutting:

- Fiber lasers produce a narrow, focused beam that allows for extremely precise cuts with minimal kerf (cut width), ideal for intricate designs and tight tolerances.

High Cutting Speed:

- Fiber lasers can cut stainless steel at high speeds, significantly improving productivity compared to traditional cutting methods.

Minimal Heat-Affected Zone (HAZ):

- The concentrated laser beam minimizes the area affected by heat, reducing the risk of warping, distortion, or discoloration.

Clean Cuts and Smooth Edges:

- Produces clean cuts with smooth edges, often eliminating the need for secondary finishing processes like deburring.

Versatility in Material Thickness:

- Capable of cutting a wide range of stainless steel thicknesses, from thin sheets to thick plates.

Automated and Computer-Controlled:

- CNC (Computer Numerical Control) technology allows for precise control over the cutting process, ensuring consistent quality and the ability to handle complex geometries.

Low Maintenance:

- Fiber lasers have fewer moving parts and a longer lifespan compared to other laser types, resulting in lower maintenance requirements.

Benefits:

Efficiency:

- High cutting speeds and automation reduce production time, increasing overall efficiency.

Cost-Effective:

- Fiber lasers are energy-efficient and have lower operational costs due to reduced power consumption and maintenance needs.

Material Savings:

- Precision cutting minimizes material waste, optimizing the use of stainless steel sheets and plates.

Flexibility:

- Suitable for a wide range of applications, from industrial manufacturing to artistic and decorative projects.

Enhanced Design Capabilities:

- The ability to cut intricate patterns and shapes opens up new design possibilities that are not achievable with traditional cutting methods.

Applications:

Automotive Industry:

- Components Manufacturing: Cutting stainless steel parts and components for vehicles, such as exhaust systems, body panels, and brackets.

- Prototyping: Creating prototypes and custom parts for vehicle design and testing.

Aerospace Industry:

- Aircraft Components: Cutting precision parts for aircraft, including structural components, brackets, and panels.

- Maintenance and Repair: Producing replacement parts and components for aircraft maintenance and repair.

Medical Devices:

- Surgical Instruments: Cutting stainless steel for surgical tools and instruments with precise and clean edges.

- Medical Equipment: Manufacturing parts for medical devices and equipment that require high precision and hygiene standards.

Industrial Manufacturing:

- Machinery Parts: Producing components for industrial machinery and equipment.

- Fabrication: General metal fabrication tasks, including the production of frames, enclosures, and fixtures.

Architecture and Construction:

- Architectural Elements: Cutting stainless steel for decorative and structural elements in buildings, such as facades, railings, and signage.

- Interior Design: Producing custom stainless steel fixtures and fittings for interior spaces.

Consumer Goods:

- Home Appliances: Cutting stainless steel parts for home appliances like refrigerators, ovens, and dishwashers.

- Furniture: Creating stainless steel components for furniture, including frames, supports, and decorative elements.

Art and Design:

- Sculptures and Installations: Cutting intricate designs for art pieces and installations.

- Jewelry and Accessories: Producing custom jewelry and fashion accessories from stainless steel.

Summary:

Fiber laser cutting machines are an excellent choice for processing stainless steel, offering high precision, efficiency, and versatility. They are widely used across various industries, including automotive, aerospace, medical, industrial manufacturing, architecture, consumer goods, and art. The technology’s ability to produce clean cuts with minimal heat-affected zones and reduced material waste makes it a valuable tool for any application requiring precision and quality in stainless steel cutting.

CN

CN AR

AR ES

ES RU

RU