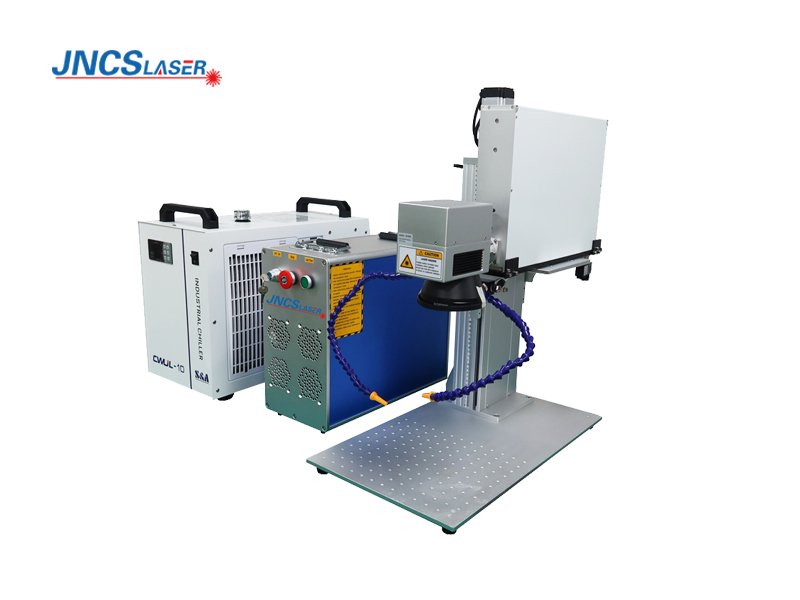

CS1325 120W 3 in 1 Fiber Laser Smart Mirror Marking/ Frosted Glass Marking/ Glass Drilling Machine

3 in 1 Fiber Laser Smart Mirror Marking/ Frosted Glass Marking/ Glass Drilling Machine

Rating:

he 3-in-1 split fiber laser smart mirror marking, frosted glass marking, and glass drilling machine offers a comprehensive solution for a wide range of glass processing applications, providing flexibility, precision, and efficiency in glass customization and fabrication.

Main Feature:

The 3-in-1 split fiber laser smart mirror marking and frosted glass marking machine, combined with glass drilling capabilities, is a versatile tool designed for a range of glass processing applications. Here’s an overview of its functionalities:

- Mirror Marking:

Laser Source: The machine is equipped with a fiber laser source capable of high-quality mirror marking on glass surfaces. The laser beam interacts with the glass, creating precise and customizable mirror-like patterns, designs, or text.

Smart Control: The machine features smart control software that allows for easy design input, customization, and adjustment of mirror marking parameters such as depth, intensity, and pattern complexity.

Applications: Mirror marking is commonly used for decorative purposes in the glass industry, such as creating intricate designs on mirrors, glass doors, tabletops, and decorative glass panels.

- Frosted Glass Marking:

Laser Parameters: The machine can be configured to perform frosted glass marking by adjusting laser parameters to create a matte, frosted appearance on glass surfaces.

Applications: Frosted glass marking is popular for applications such as privacy screens, decorative glass partitions, signage, and artistic glass designs.

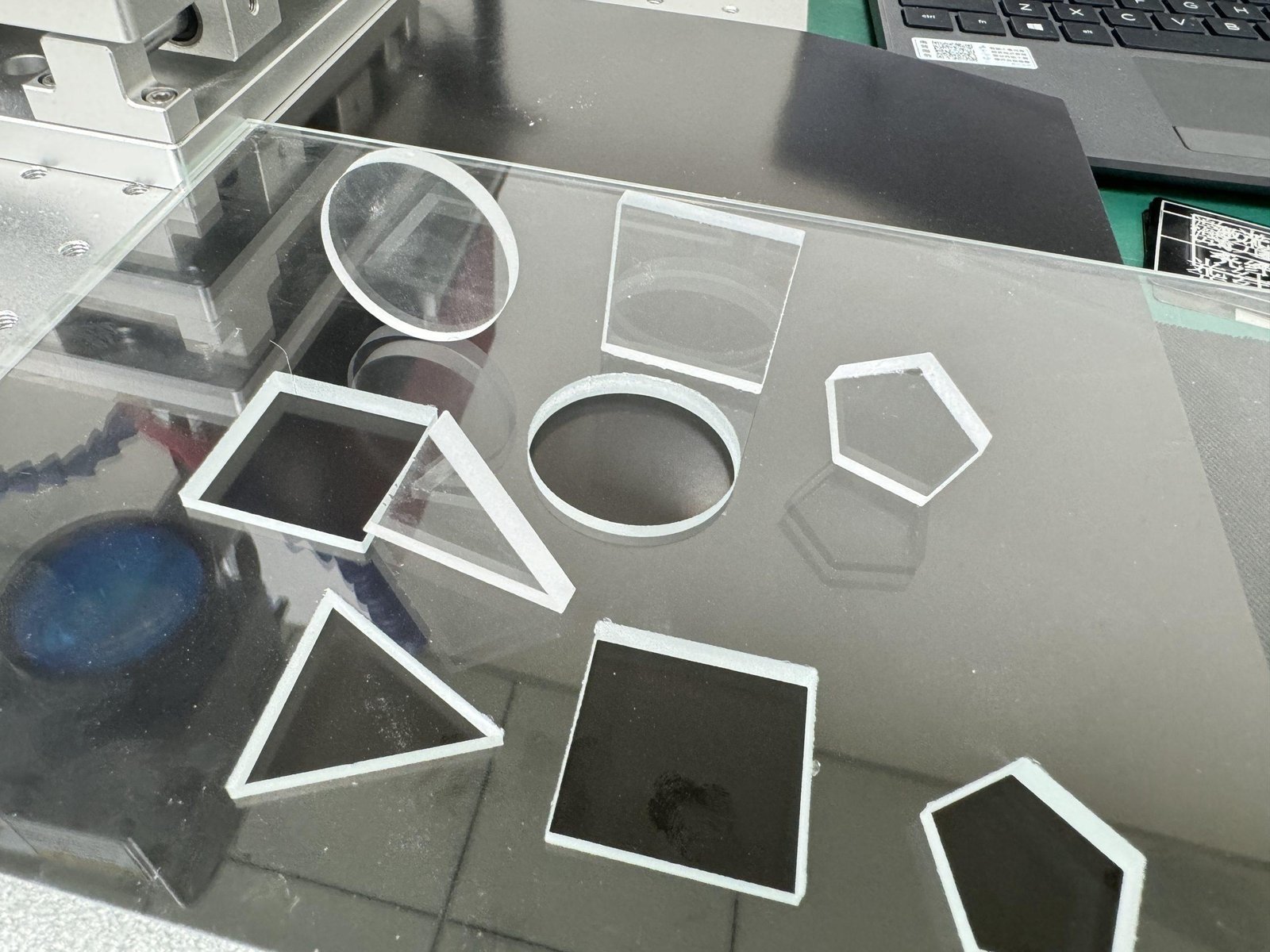

- Glass Drilling:

Drilling Capabilities: The machine is equipped with drilling capabilities using the same fiber laser source. It can create precise holes in glass materials with controlled depth and diameter.

Automation: The drilling process is automated and controlled through CNC software, allowing for accurate positioning and drilling of holes in glass components.

Applications: Glass drilling is essential for various industries, including electronics (for circuit boards), automotive (for sensors and displays), medical devices (for glass components), and architectural applications (for glass fittings and fixtures).

Customizable Effects: Users can control the level of frosting, texture, and opacity to achieve different visual effects, from light frosting to more pronounced textures.

Machine Configurations:

Controller, Servo motor, driver

high speed, high precision

raycus fiber laser 50w , optional JPT 60w, 100w

Machine Parameters:

Model | CS-F120 |

Machine table traveling size | 1300*2500mm |

Wave length of laser | 1060-1080nm |

Frequency Turning Range | 1-3000 |

Laser power | 120W |

Marking scope | Telecentric field lens (60*60mm) |

Laser sources | Fiber module |

Laser Head | Scanning head |

The minimum focus facula diameter | 20μm |

Pulse Width | 2-20ns |

Cooling ways | Water Cooling |

Power supply | 220V/ 50Hz/2kVA |

Process Material | Glass, Mirror, other metal marking |

Support format | PLT, BMP, DXF, JPG, TIF, AI etc |

Beam quality M² | <1.4 |

Indicator red light | 0.3-2 mW |

Collimated beam diameter (4σ) | 10-12mm |

Package | Standard Crate for export |

Operating temperature | 0 – 40 |

Video Tutorials & Instructional Video:

Sample Display:

How to Play Order:

- Will you please inform us the below information?

- What material will you mark?

- What is your maximum marking area?

- Do you need marking depth? Or just require marking clearly?

- We would like to recommend you suitable laser marking machine accordingly and offer you our best price.

- Will you ship machine by sea, by air or by courier? So, please tell us your nearest sea por, air port, or detailed address. We would like to check freight fee for you.

- After you confirm machine model, power, price, freight fee, then please inform us your Consignee Information ( company name, address, contact, phone number ) we will make Proforma Invoice for you to play order.

- You can remit the payment according to Proforma Invoice.

- Machine will be ready 5-7 working days after your payment.

- We will share with you machine photos and videos since machine is ready.

- After confiming all is fine, we will book shipment.

- We will share with you bill of lading, commercial invoice, packing list after shipment.

- You can operate laser marking machine according to user video and user manual.

- If any questions about using, we would like to guide you online.

CN

CN AR

AR ES

ES RU

RU