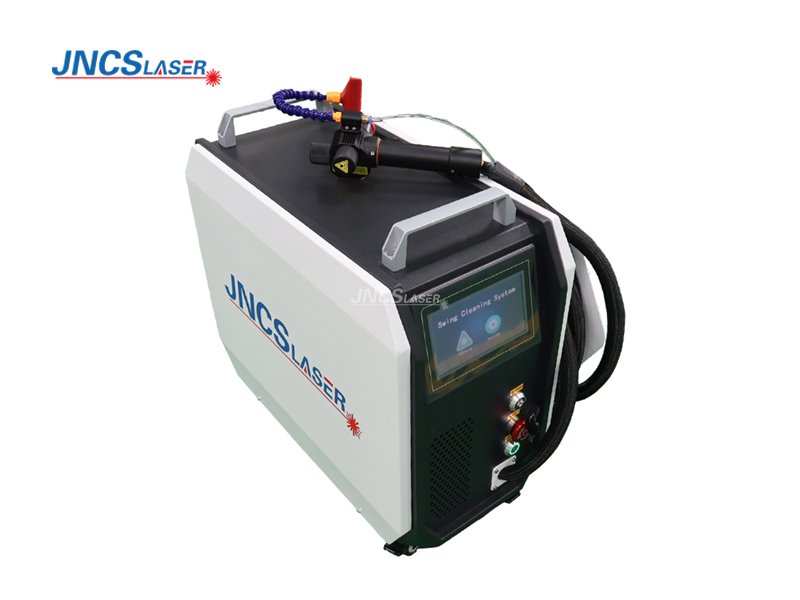

500W 1000W Pulsed Fiber Laser Cleaning Machine for removing rust, paint, coatings, grease, oxide layers

Pulsed Fiber Laser Cleaning Machine for Rust Paint Oil Removing

Rating:

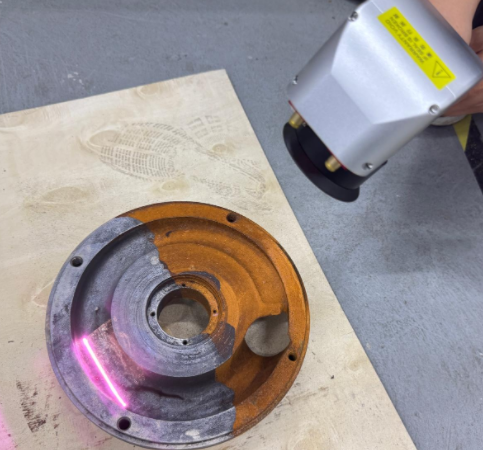

Laser cleaning is a new technology based on the interaction of laser and matter, which can achieve the effect of removing contamination and attachments on the surface of objects. Compared with traditional cleaning methods, laser cleaning has the advantages of non-contact, no damage to the substrate, precise cleaning, “green” environmental protection and online availability, and is especially suitable for high-speed online cleaning in designated areas.

Main Feature:

A pulsed fiber laser cleaning machine is a type of laser cleaning equipment that utilizes pulsed laser technology for efficient and precise cleaning applications. It provides a focused and high-energy laser beam that interacts with the surface contaminants, removing them through various mechanisms such as ablation, vaporization, and shockwave generation. Here are the main features and characteristics of a pulsed fiber laser cleaning machine:

Pulsed Laser Technology: The machine employs a pulsed fiber laser as its energy source. Pulsed lasers emit high-intensity laser pulses with controlled durations and repetition rates. This allows for precise control over the energy delivered to the surface, optimizing the cleaning process.

Versatile Cleaning Capabilities: Pulsed fiber laser cleaning machines can effectively remove a wide range of contaminants, including rust, paint, oxides, grease, oil, coatings, residues, and more. They can be used on various surfaces, including metals, plastics, composites, ceramics, and delicate materials.

High Cleaning Efficiency: The pulsed laser technology used in these machines provides high cleaning efficiency. The intense laser pulses rapidly heat and vaporize the contaminants, causing them to be expelled from the surface. This enables quick and thorough cleaning, even in hard-to-reach areas.

Non-contact and Non-abrasive Cleaning: Pulsed fiber laser cleaning is a non-contact and non-abrasive method. The laser energy removes contaminants without physically touching the surface, minimizing the risk of surface damage or scratches. It eliminates the need for chemical solvents, sandblasting, or mechanical scrubbing, making it a gentle yet effective cleaning solution.

Precise Control and Customization: Pulsed fiber laser cleaning machines offer precise control over various cleaning parameters, such as pulse duration, energy, repetition rate, and scanning patterns. This allows operators to customize the cleaning process according to the specific requirements of the application, ensuring optimal results.

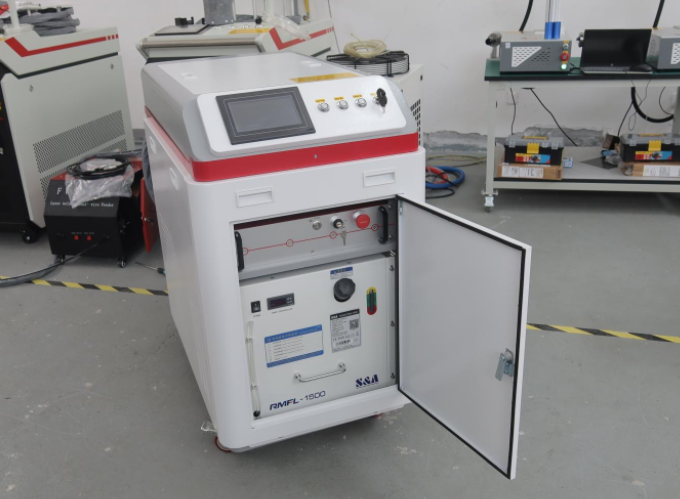

Machine Configurations:

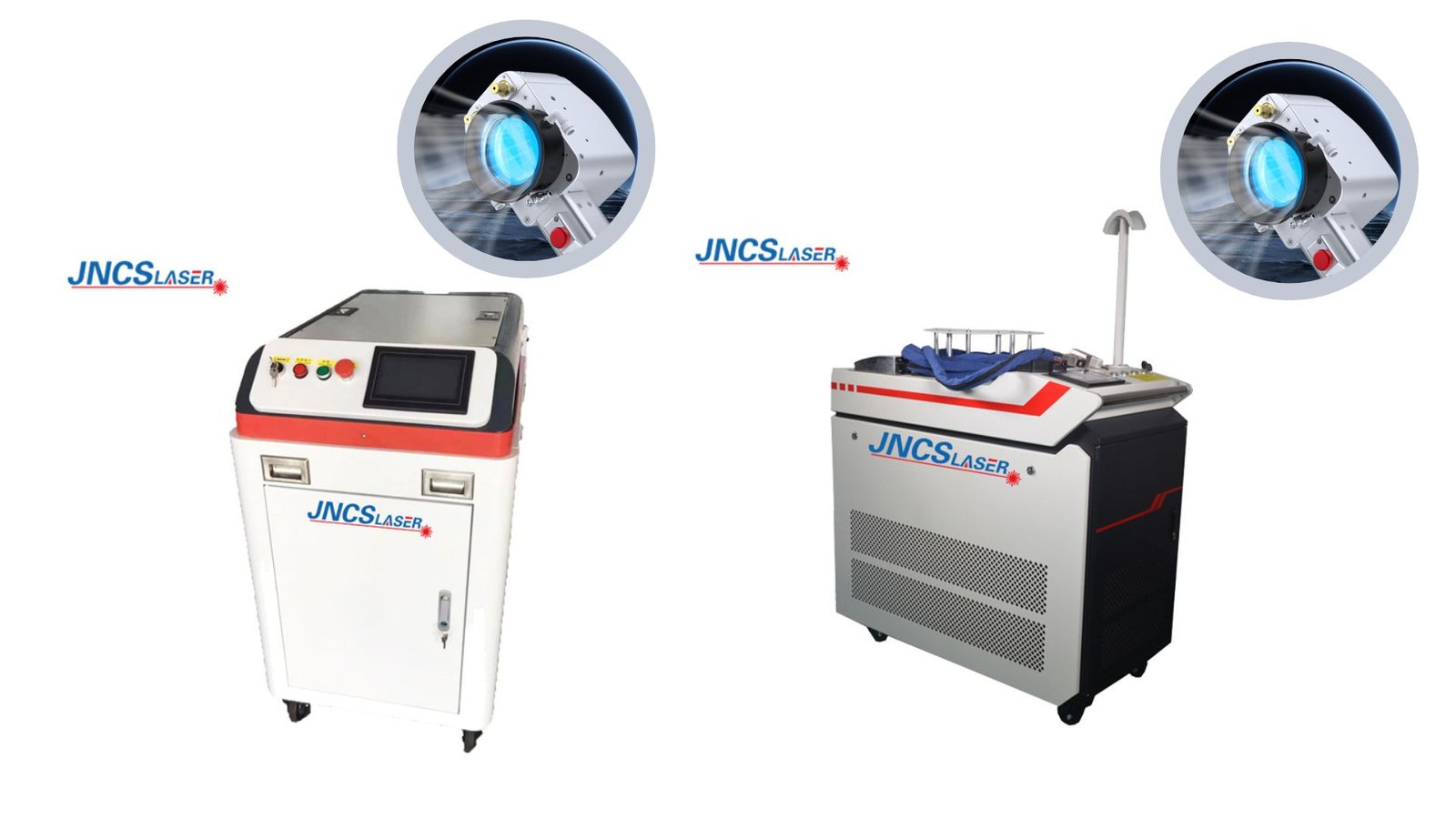

Operational Panel and Controller: The DHCP500 DHCP1000 supports eight cleaning modes and is suitable for a variety of complex cleaning scenarios. Support real-time control of laser power slow rise and slow down, better cleaning effect, no damage to the substrate. The DHCP500 DHCP1000 supports 15 languages, which can be used by users in more countries.

Handheld Double Axis cleaning Head: Small size, light weight, easy to operate,DHCP500 DHCP1000 adopts self-developed high-speed galvanometer motor, and the product structure design is more reasonable and the stability is higher. Compatible with the current market mainstream laser (OCS output), support structure customization.

Pulsed Fiber Laser : CL-500, CL-1000 500w 1000w pulsed fiber laser source, air cooling laser source, it is used for cleaning. This type of fiber laser adopts fiber-coupled output semiconductor laser for pumping, which has higher energy conversion efficiency; and the laser adopts air-cooling system, which makes the heat dissipation structure more compact, smaller and more portable; and the integrated all-fiber design makes the system maintenance-free, which is convenient for customers to use.

Industrial Water Chiller : One of the biggest convenience of the machine is the inside water chiller. It saves a lot of the machine’s dimension.It is constant temperature industrial type

Optional Design

Video Tutorials & Instructional Video:

How to Play Order:

- Will you please inform us the below information?

What material will you clean? Rust, paint, oil?

- We would like to recommend you suitable laser cleaning power 200w 300w 500w accordingly and offer you our best price.

- Will you ship machine by sea, by air? So, please tell us your nearest sea por, air port. We would like to check freight fee for you.

- After you confirm machine model, power, price, freight fee, then please inform us your consignee information ( company name, address, contact, phone number ) we will make Proforma Invoicefor you to play order.

- You can remit the payment according to Proforma Invoice.

- Machine will be ready 10-12 working days after your payment.

- We will share with you machine photos and videos since machine is ready.

- After confiming all is fine, we will book shipment.

- We will share with you bill of lading, commercial invoice, packing list after shipment.

- You can operate laser welding machine according to user video and user manual.

- If any questions about using, we would like to guide you online.

CN

CN AR

AR ES

ES RU

RU