3 Axis 4 Axis 5 Axis 6 Axis Automatic Platform Continuous Fiber Laser Welding Machine 1.5kw 2kw 3kw

3 Axis 4 Axis 5 Axis 6 Axis Automatic Platform Continuous Fiber Laser Welding Machine 1.5kw 2kw 3kw

Max. Fiber Laser source

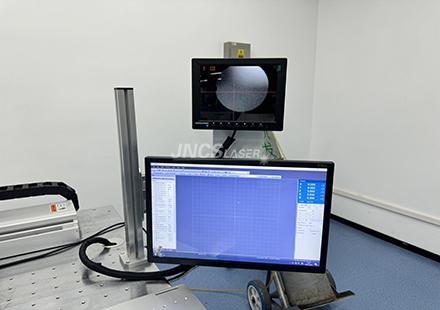

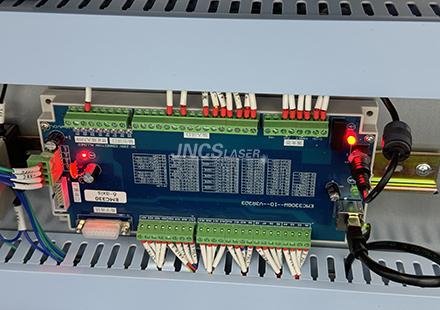

CatDSP Motion Control System

X 800mm Y300mm Z 300mm traveling size

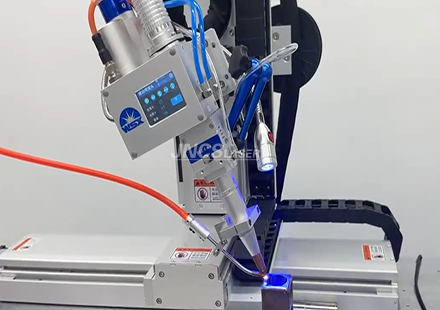

HB15-double wobble welding gun

HCFA servo motor

Industrial water chiller

CCD system Industrial Computer

Support: 4 axis 5 axis 6 axis

Main Feature:

- Laser welding is a new type of welding method and one of the important aspects of the application of laser material processing technology. Laser welding is to radiate a laser beam to the processed object. After heating the surface of the workpiece, the surface heat diffuses into the interior through heat conduction. By controlling the parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool. , After cooling to form a weld. The welding process is of thermal conductivity type, and the advantages are large aspect ratio, fast welding speed, small thermal influence range, and small workpiece deformation.

Its main technical characteristics: - The control system is a professional four-axis control system tailored for laser welding. It has powerful PC control and is easy to program,debug and maintain. It can complete automatic or semi-automatic spot welding, butt welding, stitch welding, and sealing welding. Welding of plane straight lines, arcs and arbitrary trajectories; the system is simple and reliable to operate, easy to control, simple to operate, easy to learn, easy to understand and easy to use for users;

- Equipped with three-axis automatic worktable, super large worktable, platform XY dual-axis electric module, Z-axis adopts power-off brake motor, and can be equipped with rotating shaft when it is time. For special-shaped three-dimensional products, it can realize three-dimensional laser welding, fast speed, long life accuracy high;

Customized automated tooling fixtures can be combined with assembly lines,photoelectric sensors, pneumatic fixtures and other combinations for fully automatic processing to achieve mass production of products. - It can perform time splitting or energy splitting, suitable for applications in different processing occasions, multi-station processing applications, and can be widely used in laser welding such as spot welding, continuous welding and flexible processing industries.

- Support multi-channel optical fiber output to improve welding efficiency, save equipment cost, and reduce equipment occupation space. You can choose multiple optical fiber to output light in time, or to output light at the same time according to the needs, or any combination of the two, so it can be carried out. Multi-beam simultaneous processing and multi-station processing provide conditions for more precise welding;

After the laser passes through the optical fiber, the spot becomes more uniform and stable, which improves the quality of the weld. After the laser beam is focused, a small spot can be obtained, the power density is high, and it can be accurately positioned. It can be applied to the assembly welding of micro and small workpieces in mass automated production.

Machine Configurations:

Adopting famous brands (Raycus / JPT/Max. And Germany IPG)

equipped with 1.5p water chiller, it can meet with requirements for a long time, high power welding is more stable.

Display on a video, display by connect the device, clear welding point

CatDSP is a motion control software based on object-oriented programming technology, and developed with top-down procedure, which is designed for laser machining equipment

laser power, emergency switch, allow light, PC

The welding joint adopts motor driving X, Y axis vibration lens, with a variety of swing mode, and swing welding Machining parameters such as allowing irregular welding and larger clearance can significantly improve the welding quality

Machine Parameters:

Machine Name | Automatic Fiber Laser Welding Machine |

Laser Power | 1.5KW 2KW 3KW |

X Y Z Traveling Size | 800X300X300mm |

Laser type | fiber-optic laser |

Laser Wave Length | 1080nm ±5nm |

Sport mode | Continuous/modulation |

Adjust frequency | 1000HZ |

Focus range | 150-250mm Optional |

Fiber core diameter | 50-100um |

Laser Source | Raycus / Max |

Spectroscopic method | Precision energy spectroscopy or high-speed time spectroscopy |

Fiber Length | 10M |

Cooling Mode | Water cooling |

Cooling power of chiller | 1.5P 3P |

Working Voltage | AC220V / 50Hz / 60HZ AC380V / 50Hz / 60HZ |

Package Size | 139*139*190cm 419kg machine 80*65*117cm 98kg chiller |

Gross Weight | Machine: 419kg Chiller: 98kG |

Video Tutorials & Instructional Video:

Sample Display:

Machine Application:

The fiber optic continuous welding machine has a wide range of applications. It is used in the sanitary industry: water pipe joints, reducers, tees, valves, battery industries: lithium batteries, battery packs, laser welding of electrodes, glasses industry: stainless steel, titanium Alloy and other materials for glasses buckle, precise welding of outer frame and other positions, hardware industry: impeller, kettle, water cup, stainless steel bowl, sensor, diode, aluminum alloy, mobile phone battery, door handle, shelf, etc.

How to Play Order:

- Will you please inform us the below information?

- What material will you weld? Stainless steel, iron, carbon steel, aluminum, galanized sheet?

- What is welding thickness for each kind of metal?

- We would like to recommend you suitable laser welding power 1kw 1.5kw 2kw accordingly and offer you our best price.

- Will you ship machine by sea, by air? So, please tell us your nearest sea por, air port. We would like to check freight fee for you.

- After you confirm machine model, power, price, freight fee, then please inform us your consignee information ( company name, address, contact, phone number ) we will make Proforma Invoice for you to play order.

- You can remit the payment according to Proforma Invoice.

- Machine will be ready 10-12 working days after your payment.

- We will share with you machine photos and videos since machine is ready.

- After confiming all is fine, we will book shipment.

- We will share with you bill of lading, commercial invoice, packing list after shipment.

- You can operate laser welding machine according to user video and user manual.

- If any questions about using, we would like to guide you online.

CN

CN AR

AR ES

ES RU

RU