1500W Boom Type High Speed Mold Fiber Laser Welding Machine

Laser Welding Machine for Mould Repairing

Mold laser welding machine mainly used in large-scale moulds’ repairing. the machine is controlled by Industrial micro-Computer.YAG Laser mould welding machine is use the high energy of heat that instantaneously produced by laser to melt the special-purpose welding wire and connect it with the damaged parts of the mould so it can connect with the original material firmly, after that it shows a reface by electric spark and grind & cutting and some other processing and so the mould is repaired.

Main Feature:

- Adopt imported ceramic concentrating cavity, high reflectivity, strong energy, high temperature resistance, corrosion resistance and long service life;

- equipped with 1.5P special chiller, can meet the long-term, high-power welding stability;

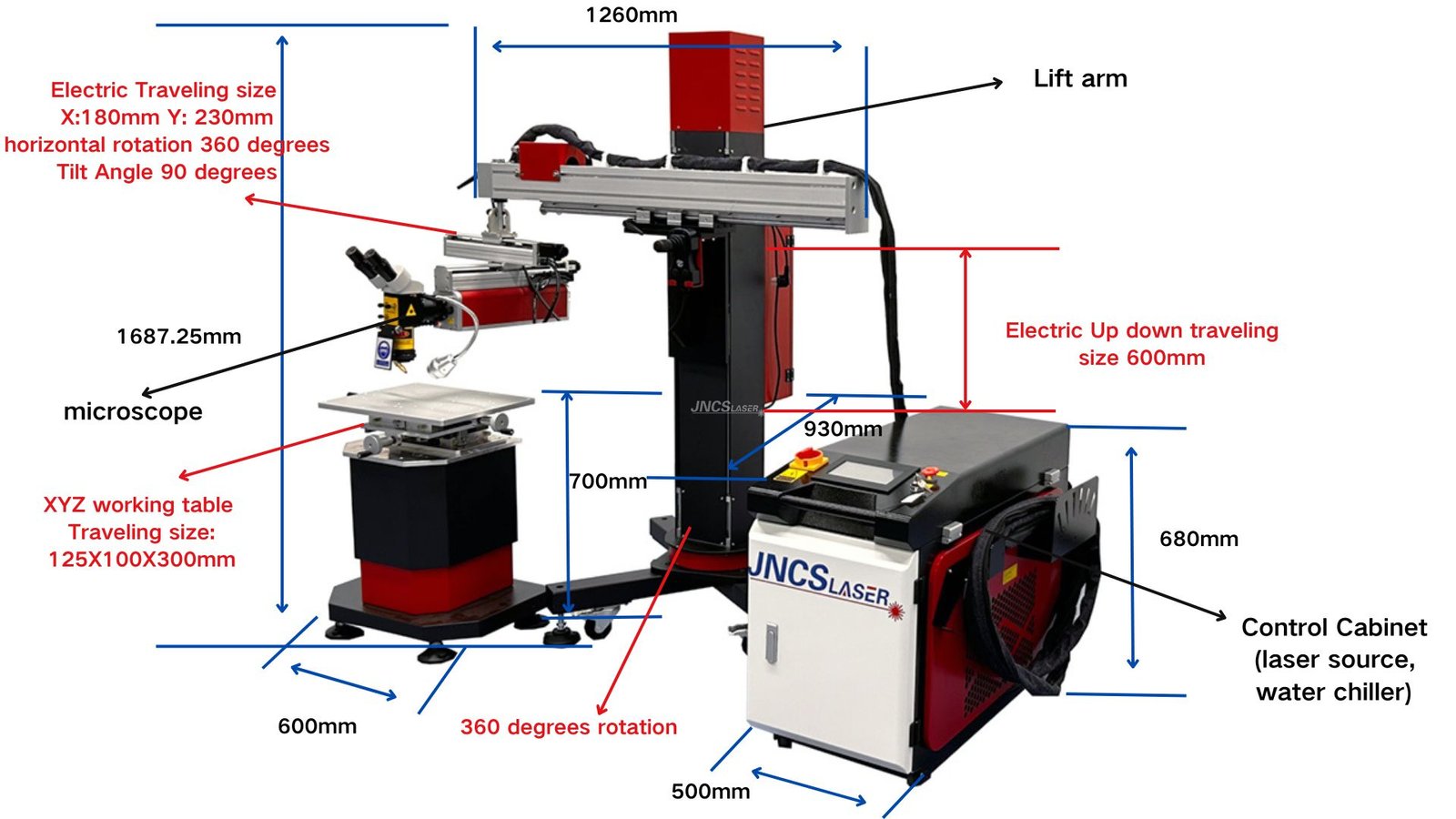

- The base of the workbench is electrically lifted and lowered. The workbench moves using precision ball screw and high-precision straight guide rail. It is light and flexible, with precise positioning and bearing capacity up to 200 kg.

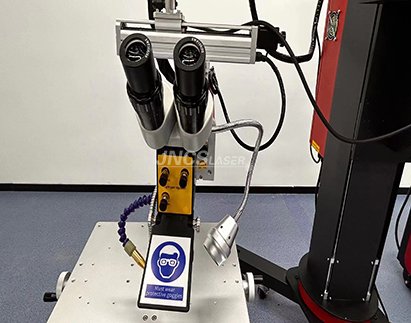

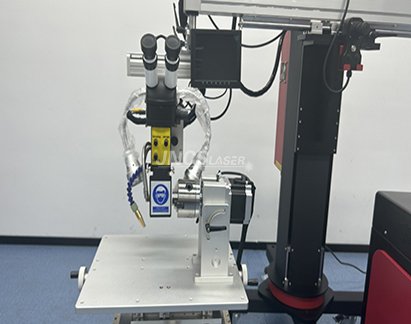

- the laser head can slide back and forth, manual lifting, the laser head can be easily rotated 180 degrees, convenient to repair any side;

- remote control all-round control, 360 degree flexible adjustment of welding angle position, suitable for all kinds of mold welding, for large molds, you can use the workbench, directly on the ground or forklift for mold welding, you can repair the welding radius of 1.5 meters, the weight of the number Tons of large molds and equipment

- The spare pulley is convenient to move, and can be moved directly to the injection molding machine to directly repair the welding without removing the mold;

- the welding depth is large, the welding is more firm, the welded part can be fully melted without pores and trachoma, and the repair marks are neat and beautiful.

Machine Configurations:

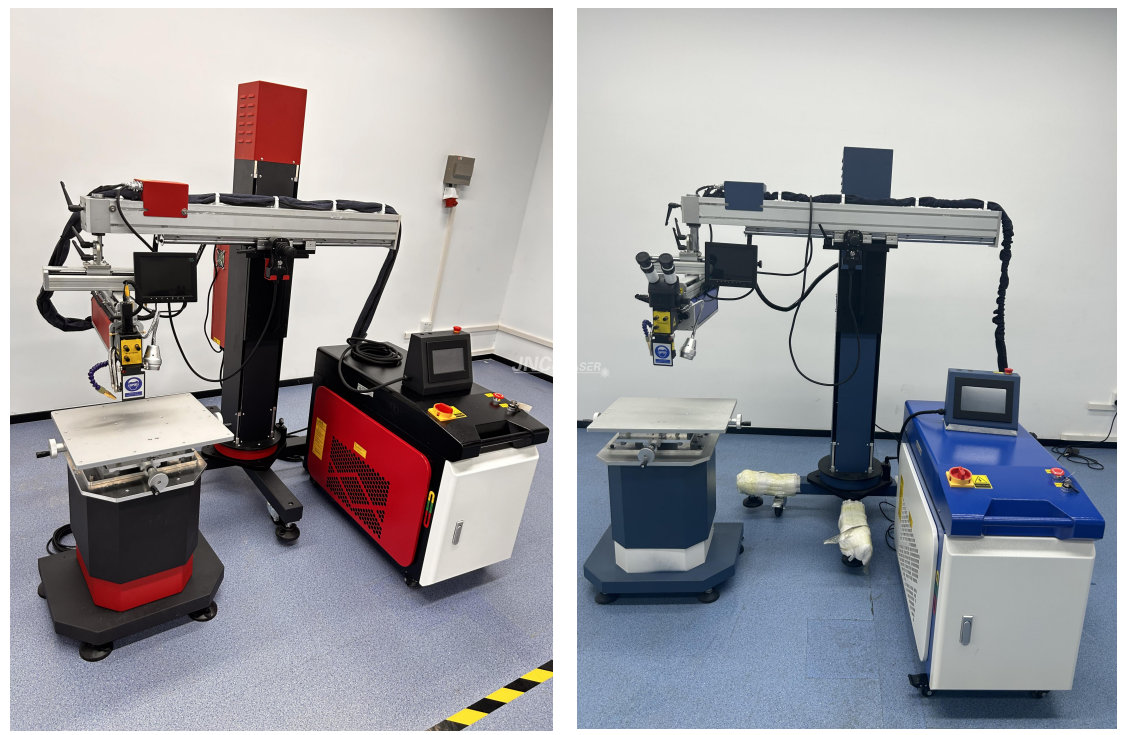

Crane Arm for big size mold repairing

Optional Parts:

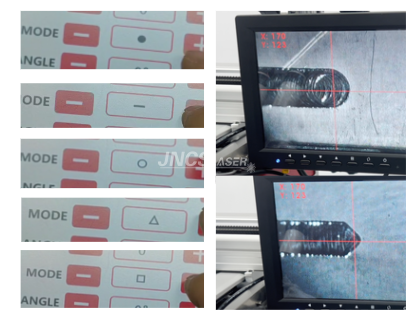

Display on a video, display by connect the device, clear welding point

Without swing head, it can be weld aluminum 0.6mm stainless steel 1.0mm With swing head, It can be weld aluminum 1.0mm stainless 1.2mm

It supports weld round part. Diameter 80mm

It can control laser path x y z direction moving, left right front back up, down, there are two buttons can emit laser, one for dot welding, one for continue welding.

Machine Parameters:

Model | CS-FL1500W CS-FL2000W CS-FL3000W | |

Rated Laser Power | 1500W 2000W 3000W | |

Laser type | Fiber laser, conventional QBH terminal | |

The laser wavelength, | 1080 +- 10nm | |

Movement patterns | Continuous, pulse | |

Maximum regulation frequency | 25Hz(customiza ble) | |

Laser welding depth | ≤ 3.0mm (material dependent) | |

Fiber core diameter | 50micro ns | |

Fiber line length | > 8 m | |

Spectroscop ic methods | Precision energy splitting or high speed time splitting | |

The light pattern | QCW/PWM/C W | |

bearing capacity of three dimensional load-bearing table | 150kg | |

Aiming and positioning system | The micro scope (optional CCD display | |

Rated power | 5.6KW | |

Cooling way | Water cooling (double temperature and double control) | |

Demand for electricity | 1500w 2000w AC220V 1 phase 3000W AC380V 3 phase | |

Package Size and Gross Weight | 149*70*121cm Machine control box and Work Table | 228kg |

| 84*85*184cm Lifting Arm | 171kg |

Video Tutorials & Instructional Video:

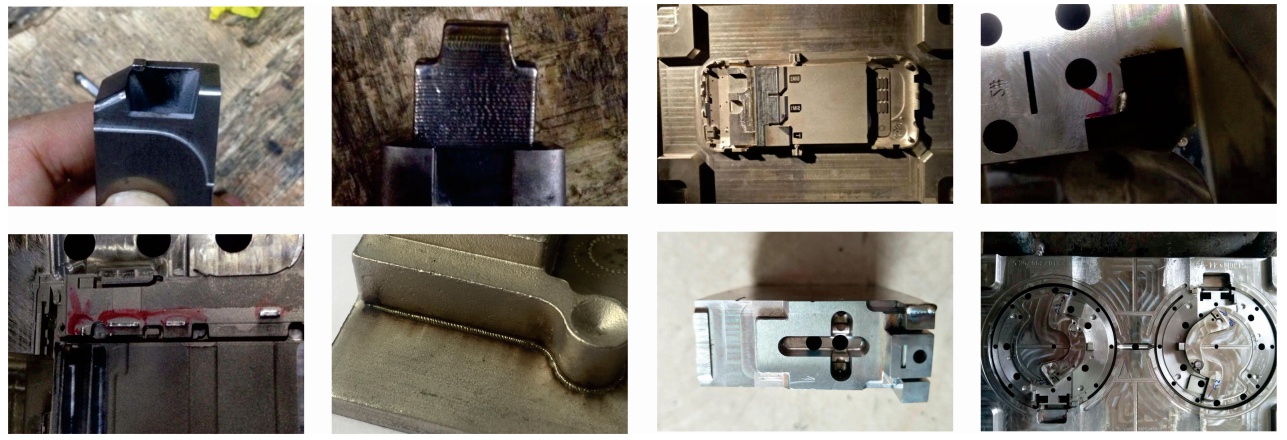

Sample Display:

mould repair laser welding machine can be widely used in many fields, such as as mold laser welding machine widely used in molds, precision injection molding, die casting and punching mold, stainless steel products and other hard materials cracks, chipping, grinding and wear seal repair, welding, cell phones, jewelry, electronics, sensors, precision machinery, communications, crafts and other industries.

How to Play Order:

- Will you please inform us the below information?

- What material will you weld?

- Will you please share with us your sample photos?

- We would like to recommend you suitable laser welding machine accordingly and offer you our best price.

- Will you ship machine by sea, by air ? So, please tell us your nearest sea por, air port. We would like to check freight fee for you.

- After you confirm machine model, power, price, freight fee, then please inform us your Consignee Information ( company name, address, contact, phone number ) we will make Proforma Invoice for you to play order.

- You can remit the payment according to Proforma Invoice.

- Machine will be ready 10-15 working days after your payment.

- We will share with you machine photos and videos since machine is ready.

- After confiming all is fine, we will book shipment.

- We will share with you bill of lading, commercial invoice, packing list after shipment.

- You can operate laser welding machine according to user video and user manual.

- If any questions about using, we would like to guide you online.

CN

CN AR

AR ES

ES RU

RU