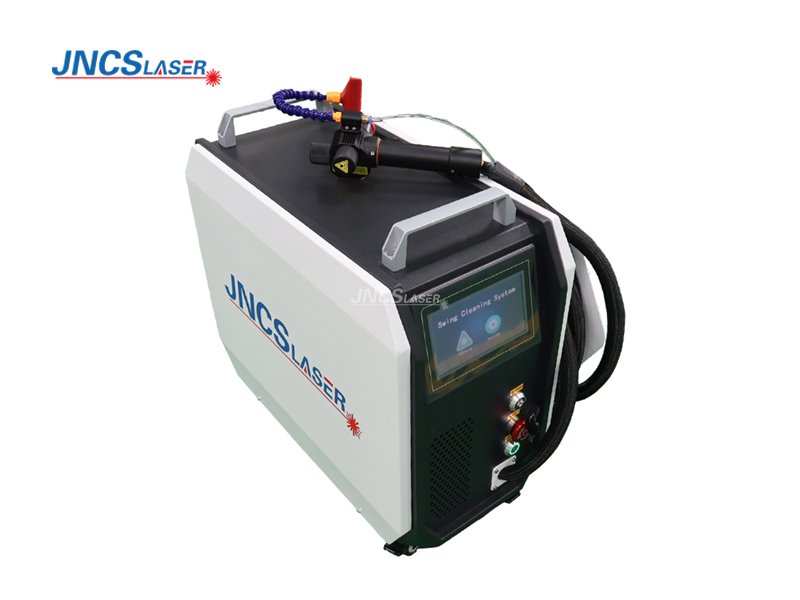

pulsed fiber laser cleaning machine for paint removal

A 300W 15mJ pulsed fiber laser cleaning machine is a high-precision industrial tool used for surface cleaning, rust removal, paint stripping, and other surface treatment applications. Its pulsed laser technology allows for controlled energy delivery, making it suitable for delicate or precise cleaning tasks. Below are some key applications of this machine:

1. Industrial Cleaning and Maintenance

– **Rust and Oxide Removal**: Effectively removes rust, oxides, and corrosion from metal surfaces (e.g., steel, aluminum, copper) without damaging the substrate.

– **Paint and Coating Removal**: Strips paint, coatings, and varnishes from surfaces, preparing them for recoating or inspection.

– **Mold Cleaning**: Cleans molds and dies in manufacturing processes, ensuring precision and extending their lifespan.

2. Automotive and Aerospace Industries

– **Engine Parts Cleaning**: Removes carbon deposits, grease, and contaminants from engine components.

– **Aircraft Surface Maintenance**: Cleans aircraft surfaces, removing paint, rust, and other contaminants without damaging the underlying material.

– **Welding Seam Cleaning**: Cleans welding seams and removes spatter, ensuring smooth and clean surfaces.

3. Cultural Heritage and Art Restoration

– **Historical Artifact Cleaning**: Safely removes dirt, corrosion, and oxidation from historical artifacts, sculptures, and monuments without causing damage.

– **Paint Layer Restoration**: Precisely removes unwanted layers of paint or coatings from artworks and historical structures.

4. Electronics and Precision Engineering

– **Circuit Board Cleaning**: Removes contaminants, oxides, and residues from electronic components and circuit boards.

– **Precision Part Cleaning**: Cleans delicate parts and components in industries like medical devices, optics, and semiconductors.

5. Construction and Infrastructure

– **Bridge and Pipeline Maintenance**: Removes rust, paint, and contaminants from bridges, pipelines, and other infrastructure.

– **Concrete Surface Cleaning**: Cleans concrete surfaces, removing stains, graffiti, and coatings.

6. Jewelry and Metalworking

– **Jewelry Cleaning**: Removes tarnish, oxidation, and contaminants from jewelry and precious metals.

– **Metal Surface Preparation**: Prepares metal surfaces for welding, coating, or further processing.

Advantages of a 300W 15mJ Pulsed Fiber Laser Cleaning Machine

– **Non-Abrasive**: No physical contact with the surface, reducing the risk of damage.

– **Eco-Friendly**: No chemicals or abrasive materials are used, making it environmentally friendly.

– **Precision**: High control over energy output allows for precise cleaning of intricate or delicate surfaces.

– **Efficiency**: Faster and more efficient than traditional cleaning methods like sandblasting or chemical cleaning.

– **Versatility**: Suitable for a wide range of materials, including metals, plastics, ceramics, and composites.

Materials Suitable for Cleaning

– Metals: Steel, aluminum, copper, titanium, etc.

– Plastics and composites.

– Stone and concrete.

– Glass and ceramics.

This machine is ideal for industries requiring high precision, minimal substrate damage, and environmentally friendly cleaning solutions.

CN

CN AR

AR ES

ES RU

RU