What are difference between single wobble fiber laser welder and double wobble fiber laser welder

The terms “single-wobble” and “double-wobble” refer to the motion patterns or oscillations of the laser beam during the welding process in fiber laser welders. These patterns are used to enhance the welding performance and control the heat distribution in the welded area. Here are the primary differences between single-wobble and double-wobble fiber laser welders:

Single-Wobble Fiber Laser Welder:

- Motion Pattern:

- In a single-wobble configuration, the laser beam oscillates or wobbles in a single direction during the welding process. Typically, it moves back and forth along one axis.

- Heat Distribution:

- The single-wobble pattern is effective in spreading the heat more evenly across the weld seam. This helps control the width and depth of the weld, minimizing the risk of overheating and distortion.

- Applications:

- Single-wobble configurations are often used for applications where a consistent and controlled weld bead is required. It is suitable for welding thin materials and applications where precision is critical.

Double-Wobble Fiber Laser Welder:

- Motion Pattern:

- In a double-wobble configuration, the laser beam oscillates in two directions during the welding process. It moves back and forth along two perpendicular axes.

- Enhanced Heat Control:

- The double-wobble pattern provides even more control over the heat distribution. By oscillating in two directions, it can further improve the bead profile, reduce porosity, and enhance the overall quality of the weld.

- Versatility:

- Double-wobble configurations are versatile and can be applied to a broader range of materials and thicknesses. They are particularly useful for applications where precise control over the weld geometry and heat input is crucial.

- Reduced Heat-Affected Zone (HAZ):

- The double-wobble pattern can help reduce the size of the heat-affected zone, which is the area around the weld where the material experiences thermal changes. This can be important for materials sensitive to heat.

Considerations:

- Material Thickness:

- Single-wobble configurations may be sufficient for thinner materials, while double-wobble configurations are often preferred for thicker materials.

- Weld Quality Requirements:

- The choice between single-wobble and double-wobble configurations depends on the specific welding requirements, including the desired weld quality, material type, and application.

- Machine Settings:

- Both configurations require precise control over laser power, speed, and wobble parameters to achieve optimal welding results.

Welcome to contact us for more details.

- Email: info@jncslaser.com

- Whatsapp: 0086 18254116182

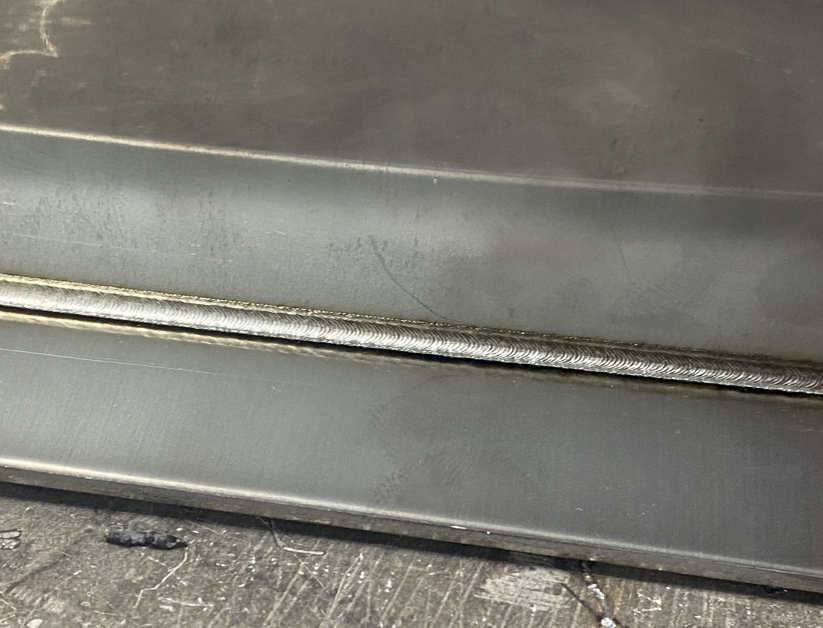

Single Wobble Fiber Laser Welding Machine

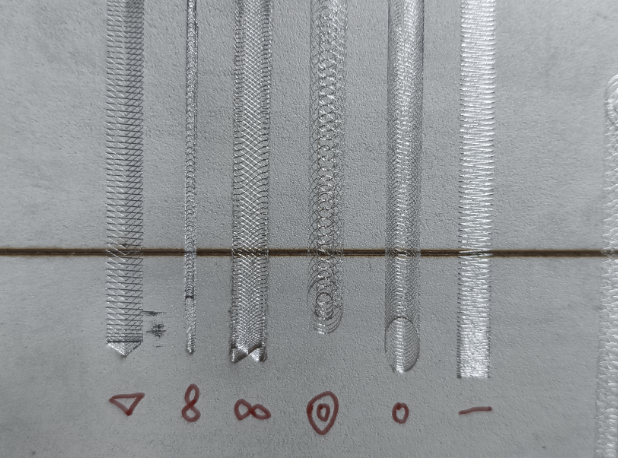

Double Wobble Fiber Laser Welding Machine

CN

CN AR

AR ES

ES RU

RU