How to Choose Between Continuous and Pulse Laser Cleaning Machine?

Laser cleaning machines are devices used to remove surface dirt from substrates using laser technology. Currently, there are two main types of laser cleaning machines on the market: pulse laser cleaning machines and continuous laser cleaning machines.

Many customers come to ask us how to choose between continuous laser cleaning machine and pulse laser cleaning machine. This may be of interest to many clients involved in rust or paint removal in a corporate business. This blog will answer your questions. You’ll learn the difference between continuous and pulsed laser cleaners, and how to choose based on your needs.

Major difference between continuous and pulse laser cleaning machine

Laser source

The main difference between these two types of laser cleaning machines is the type of laser used. Pulse laser cleaning machines use pulsed laser, while continuous laser cleaning machines use continuous laser.

Cleaning principle

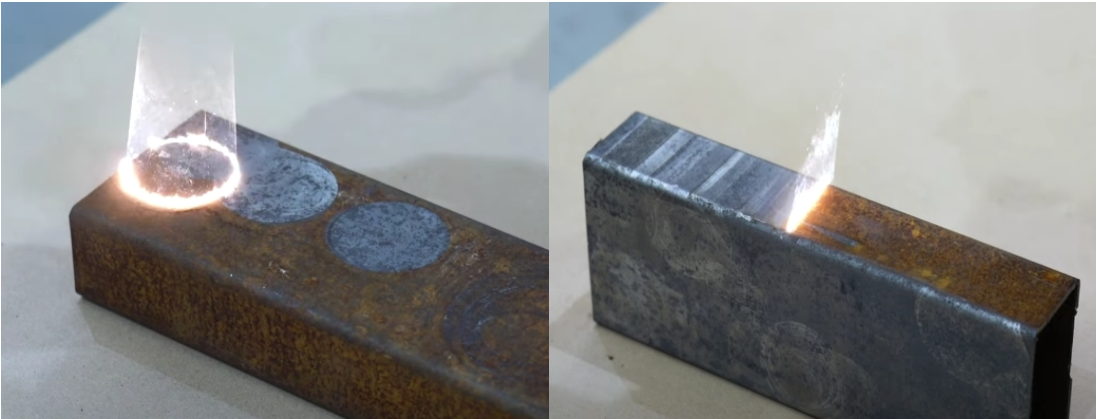

Secondly, the cleaning principle of the two types of machines is also different. Continuous laser cleaning machines use high-temperature burning to clean dirt, while pulse laser cleaning machines use oscillation to break down dirt. Therefore, pulse laser cleaning machines cause relatively less damage to the substrate.

Price

Additionally, the price difference is quite significant. The price of a pulse laser cleaning machine is more than 3-4 times higher than that of a continuous laser cleaning machine. This is also a factor that many customers consider when choosing a laser cleaning machine.

Cleaning results

The continuous laser cleaning machine and pulse laser cleaning machine are also different in cleaning speed and cleaning effect. The continuous laser cleaning machine is suitable for cleaning large-area, thin-thick stains, with fast cleaning speed and good effect. However, the cleaning speed of the pulse laser cleaning machine is relatively slow, and it is suitable for cleaning small areas and thick stains.

Which one is more suitable to clean paint?

If the material to be cleaned is paint, pulse laser cleaning machines are more suitable. Due to the strong adhesion of paint, it is more difficult to clean than rust and oil. When using a continuous laser cleaning machine to clean paint, the laser burns the surface of the material for a longer time, which may cause more damage to the substrate. If the customer requires good cleaning results and has a sufficient budget, we recommend choosing a pulse laser cleaning machine. This can improve cleaning efficiency and ensure good cleaning results.

Another thing to note is that if the dirt and the substrate material are two different substances, pulse laser cleaning machines are more suitable. Since the cleaning process of pulse laser cleaning machines uses oscillation to separate dirt, it is more conducive to separating dirt and substrate materials that are two different substances.

JNCSLASER laser cleaning machine recommendation

200W pulse laser cleaning machine

Many customers choose the pulse laser cleaning machine because it has zero damage to the substrate after cleaning the surface of the material. This makes the pulse cleaner an indispensable device for cleaning some delicate model or part applications.

The common cleaning width of the handheld laser cleaning gun is 200mm, and can be customized to 300mm as customer required. It is widely used to clean the rust and grease of stainless steel, carbon steel, and other alloys.

1500W continuous laser handheld cleaning machine

This is the most hot-sale JNCSLASER continuous laser cleaning machine with a laser power of 1500W. It is quite popular among customers who are engaged in vehicle repair, construction contraction, window and door making, and other industries.

Conclusion

For application scenarios that require strict control of the temperature rise of the substrate and require the substrate to be non-destructive, such as molds, brake pads, precision parts, etc., customers should choose pulse laser cleaning machines. For some large-scale steel structures, pipelines, etc., due to their large volume and fast heat dissipation, and low requirements for substrate damage, customers can choose continuous laser cleaning machines. In summary, whether to choose a continuous laser cleaning machine or a pulse laser cleaning machine depends on your specific cleaning needs. We will recommend the most suitable laser cleaning machine for you within you budget.

Welcome to contact us for more details.

- Email: info@jncslaser.com

- Whatsapp: 0086 18254116182

CN

CN AR

AR ES

ES RU

RU