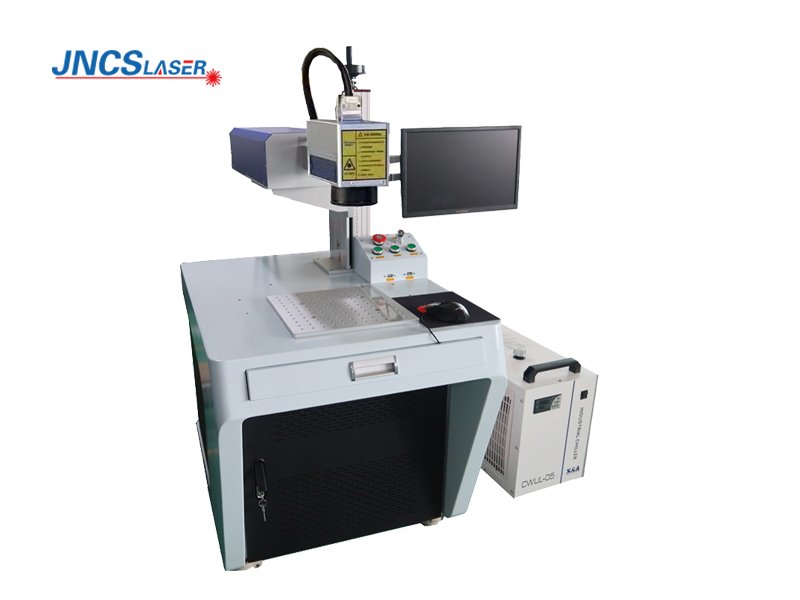

DPSS 55W Diode-Pumped Solid-State Laser borosilicate Glass Drilling Machine

Main Feature:

Diode-Pumped Solid-State (DPSS) Laser Source:

- The machine is equipped with a DPSS laser source with a power output of 55W. DPSS lasers offer high beam quality and energy efficiency, making them suitable for precise drilling applications.

High Borosilicate Glass Compatibility:

- The machine is specifically designed to work with high borosilicate glass, which is known for its high thermal and chemical resistance. This type of glass is commonly used in laboratory glassware, medical devices, and industrial applications.

High Precision Drilling:

- The DPSS laser source provides high precision drilling capabilities, allowing for the creation of small, accurate, and clean holes in high borosilicate glass. This is essential for applications that require precise hole dimensions and quality finishes.

CNC Control System:

- The machine features a computer numerical control (CNC) system that controls the movement of the laser beam and the positioning of the high borosilicate glass workpiece. This ensures accurate and repeatable drilling operations.

Cooling System:

- To prevent heat buildup and potential thermal damage to the glass, the machine is equipped with a cooling system. This may include air or water cooling to maintain optimal operating conditions during the drilling process.

Versatile Applications:

- The machine can be used for a variety of applications in industries such as electronics (for drilling glass substrates), medical devices (for drilling glass components), laboratory equipment (for drilling glassware), and industrial manufacturing (for drilling glass parts).

User-Friendly Interface:

- The machine is designed with a user-friendly interface that allows operators to set parameters, control the drilling process, and monitor the progress easily. This ensures efficient and effective operation of the drilling machine.

Safety Features:

- Safety features such as interlocks, protective enclosures, and laser safety protocols are typically incorporated into the machine to ensure safe operation for operators and prevent accidents.

Overall, a DPSS 55W laser high borosilicate glass drilling machine offers high precision, efficiency, and versatility for drilling holes in high borosilicate glass materials, making it a valuable tool for various industrial and scientific applications that require precise glass drilling capabilities.

Machine Configurations:

Brand Name: Huaray High quality Precise position

High Speed, high precision Software: Markingmate

High Speed, high precision Brand Name: sino galvo

Foot Switch Protect Goggles U disk with software Spanner Keys Screws Ruler Power Cable

1. Plastic Film 2. Foam 3. Plywood Package

Machine Optional Parts:

Diameter: 80mm

Smoke purifier is mainly used for the purification of smoke and dust produced in marking, cutting, and other processes as well as the recovery of rare metals and precious materials

Machine Parameters:

Model | CS-DPSS55 |

Laser output power | 55W |

Beam size | 4.3mm |

Beam size of focusing

| 70um |

Pulse width

| 16.0ns |

Pulse repetition frequency adjustable

| 60-200khz |

Cooling ways | Water Cooling |

borosilicate glass cutting diameter | 0.5-70mm |

Cutting thickness | Maximum 10mm |

Power supply | AC220V/ 50Hz/2kVA |

Support format | PLT, BMP, DXF, JPG, TIF, AI etc |

Package | Standard Crate for export |

Video Tutorials & Instructional Video:

Sample Display:

Applications:

Electronics Industry:

Glass drilling machines are used in the electronics industry for drilling holes in glass substrates used in electronic components such as circuit boards, displays, and sensors.

Automotive Industry:

In the automotive sector, these machines are used for drilling holes in automotive glass for sensors, cameras, and other integrated systems.

Medical Devices:

Glass drilling machines play a crucial role in the medical device industry for manufacturing components used in medical instruments, implants, and laboratory equipment.

Aerospace and Defense:

These machines are utilized in aerospace and defense applications for drilling precise holes in glass components used in aircraft, satellites, and military equipment.

Optical Industry:

In the optical industry, these machines are used for drilling holes in glass lenses, prisms, and other optical components.

Art and Decor:

Glass drilling machines can also be used in artistic and decorative applications for creating intricate patterns, designs, or perforations in glass artworks and decorative items.

Overall, a diode-pumped solid-state laser glass drilling machine offers high precision, speed, and versatility in drilling holes in glass materials, making it a valuable tool in various industries and applications.

How to Play Order:

- Will you please inform us the below information?

- What material will you mark?

- What is your maximum marking area?

- We would like to recommend you suitable laser marking machine accordingly and offer you our best price.

- Will you ship machine by sea, by air or by courier? So, please tell us your nearest sea por, air port, or detailed address. We would like to check freight fee for you.

- After you confirm machine model, power, price, freight fee, then please inform us your Consignee Information ( company name, address, contact, phone number ) we will make Proforma Invoice for you to play order.

- You can remit the payment according to Proforma Invoice.

- Machine will be ready 5-7 working days after your payment.

- We will share with you machine photos and videos since machine is ready.

- After confiming all is fine, we will book shipment.

- We will share with you bill of lading, commercial invoice, packing list after shipment.

- You can operate laser marking machine according to user video and user manual.

- If any questions about using, we would like to guide you online.

CN

CN AR

AR ES

ES RU

RU