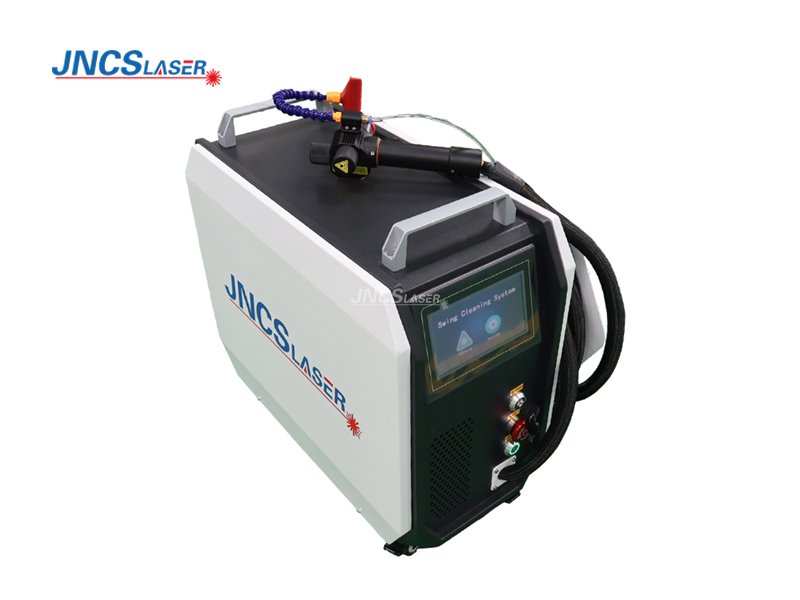

Pulsed Fiber Laser Cleaning for Auto Parts

A 300W 15mJ pulsed fiber laser cleaning machine is a powerful tool for surface cleaning, rust removal, paint stripping, and coating removal. When applied to **auto parts**, it offers a precise, non-abrasive, and eco-friendly solution for maintaining and restoring components. Here are some key applications of this technology in the automotive industry:

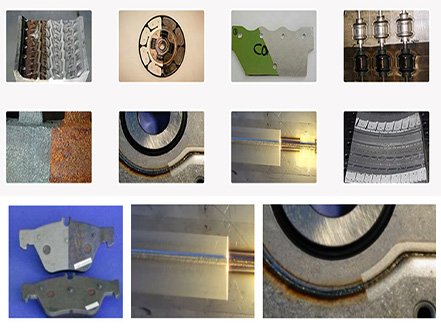

1. Rust and Oxide Removal

– **Application**: Removes rust, oxidation, and corrosion from metal auto parts such as brake discs, engine components, chassis, and exhaust systems.

– **Advantages**:

– Non-contact process that preserves the base material.

– Eliminates the need for abrasive methods like sandblasting or chemical treatments.

– Ideal for intricate parts with complex geometries.

2. Paint and Coating Removal

– **Application**: Strips paint, varnish, and other coatings from car bodies, wheels, and other components without damaging the underlying material.

– **Advantages**:

– Precise control over the cleaning process.

– Environmentally friendly, as it doesn’t involve chemicals or generate hazardous waste.

– Prepares surfaces for repainting or recoating.

3. Mold and Contaminant Removal

– **Application**: Cleans molds used in the production of auto parts, such as plastic or rubber components.

– **Advantages**:

– Removes residues like grease, oil, and carbon deposits.

– Extends the lifespan of molds by maintaining their surface quality.

4. Welding Seam Cleaning

– **Application**: Cleans welding seams and heat-affected zones (HAZ) on auto parts, removing oxides, slag, and discoloration.

– **Advantages**:

– Improves the appearance and quality of welded joints.

– Prepares surfaces for further processing or inspection.

5. Pre-Treatment for Adhesive Bonding or Welding

– **Application**: Prepares surfaces by removing contaminants, oxides, and coatings to ensure strong adhesion or welding.

– **Advantages**:

– Enhances the bonding strength of adhesives or welds.

– Reduces the risk of defects in critical components.

6. Restoration of Vintage or Classic Car Parts

– **Application**: Cleans and restores old or vintage auto parts without damaging their original structure.

– **Advantages**:

– Preserves the integrity of delicate or historical components.

– Removes decades of rust, paint, and grime effectively.

7. Cleaning of Engine Components

– **Application**: Removes carbon deposits, oil residues, and other contaminants from engine parts like pistons, cylinder heads, and valves.

– **Advantages**:

– Improves engine performance and longevity.

– Reduces maintenance time and costs.

8. Surface Preparation for Inspection

– **Application**: Prepares auto parts for non-destructive testing (NDT) or quality inspection by removing surface contaminants.

– **Advantages**:

– Ensures accurate inspection results.

– Cleans hard-to-reach areas effectively.

—

Key Benefits of Using a 300W 15mJ Pulsed Fiber Laser Cleaning Machine

– **Precision**: The pulsed laser allows for controlled energy delivery, minimizing heat input and avoiding damage to the substrate.

– **Efficiency**: High power (300W) and pulse energy (15mJ) enable fast cleaning of large or heavily contaminated surfaces.

– **Eco-Friendly**: No chemicals, solvents, or abrasive media are used, reducing environmental impact.

– **Versatility**: Suitable for a wide range of materials, including steel, aluminum, copper, and composites.

– **Cost-Effective**: Reduces labor and material costs compared to traditional cleaning methods.

Examples of Auto Parts Suitable for Laser Cleaning

– **Brake discs and calipers**

– **Engine blocks and cylinder heads**

– **Transmission components**

– **Exhaust systems**

– **Wheels and rims**

– **Chassis and suspension parts**

– **Welded assemblies**

Conclusion

The 300W 15mJ pulsed fiber laser cleaning machine is an advanced solution for maintaining, restoring, and preparing auto parts. Its precision, efficiency, and eco-friendliness make it a valuable tool for automotive manufacturers, repair shops, and restoration specialists. By adopting this technology, businesses can improve the quality and durability of auto parts while reducing operational costs and environmental impact.

pulsed fiber laser cleaning machine working video:

Por favor, entre em contato conosco para mais detalhes:

Os direitos autorais pertencem a JNCSLASER

E-mail: info@jncslaser.com

Whatsapp/Wechat: 0086 18254116182

CN

CN AR

AR ES

ES RU

RU