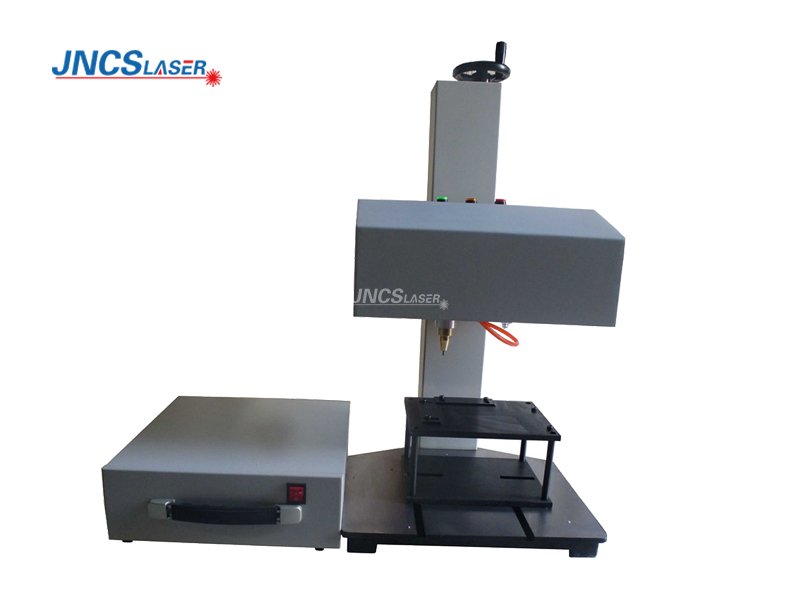

Portable CNC Pneumatic Dot Peen Marking Machine

Portable CNC Pneumatic Dot Peen Marking Machine

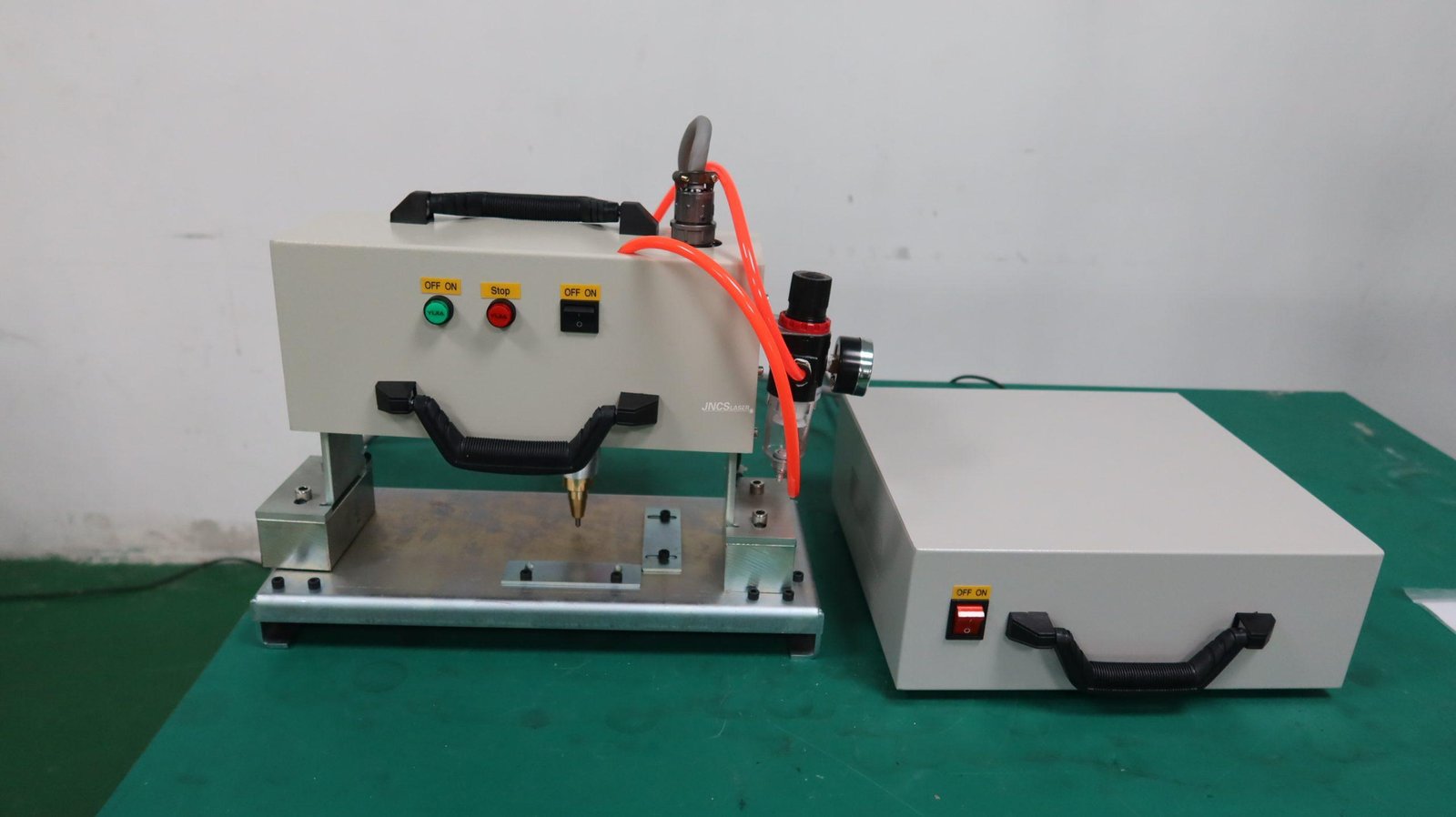

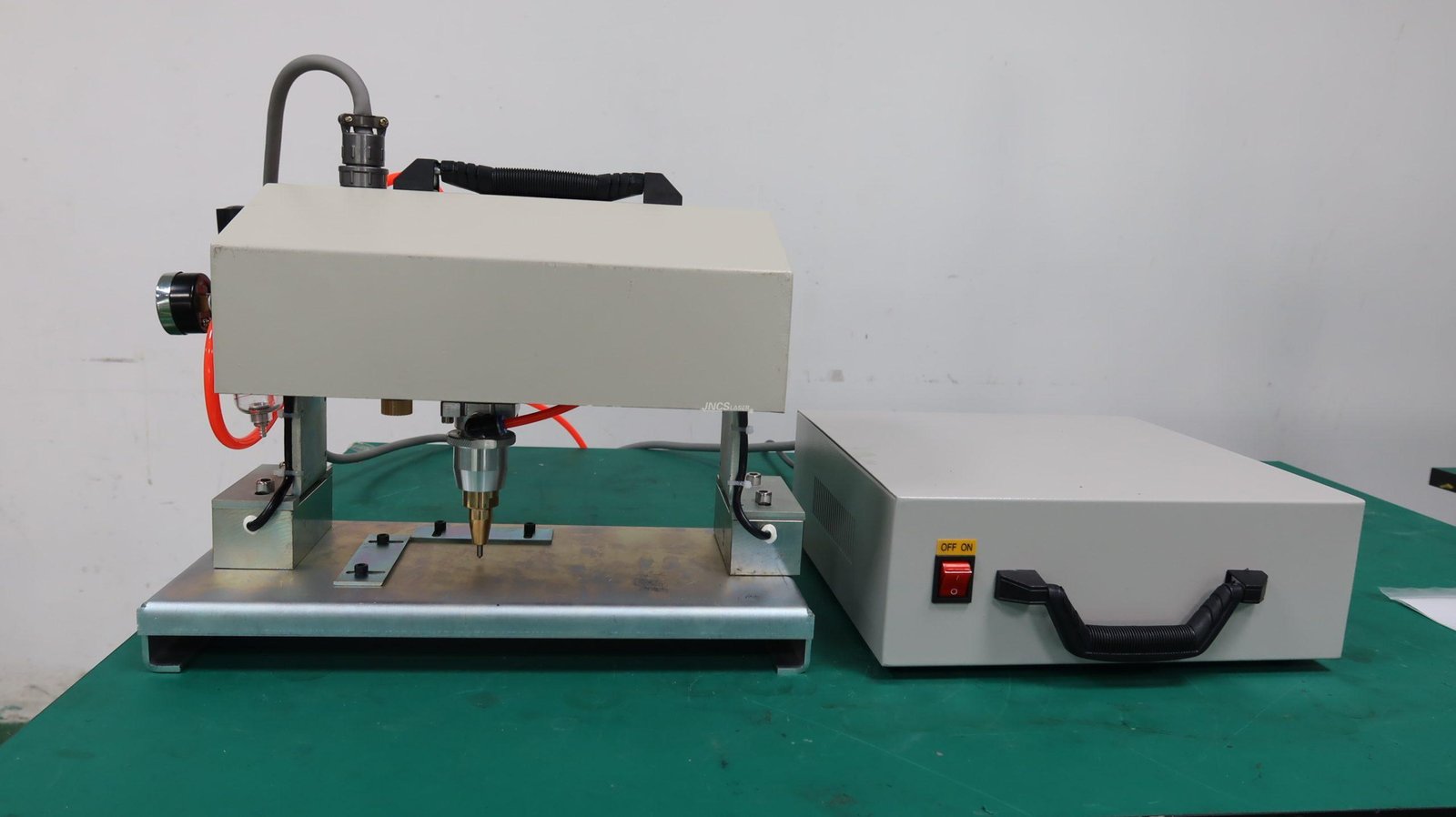

- pneumatic desktop dot peen marking machine designed for marking metal nameplates and metal parts is an efficient and cost-effective tool for producing permanent, high-precision markings on metal surfaces. The machine uses a pneumatically-driven pin to impact the surface of the metal, creating dots that form letters, numbers, logos, or codes.

Caracteristica principal:

pneumatic desktop dot peen marking machine designed for marking metal nameplates y metal parts is an efficient and cost-effective tool for producing permanent, high-precision markings on metal surfaces. The machine uses a pneumatically-driven pin to impact the surface of the metal, creating dots that form letters, numbers, logos, or codes.

Uses a pneumatically driven stylus to create durable, precise marks on metal surfaces. The marking can include alphanumeric characters, logos, barcodes, and serial numbers.

Ideal for applications where permanent, long-lasting marks are required, such as identification, traceability, and branding on metal parts.

The marking pin is made from hard-wearing materials like tungsten carbide, ensuring long service life and the ability to handle tough metals.

Marking serial numbers, batch codes, and part numbers on small metal components like gears, brackets, and fasteners for identification and traceability.

Configuraciones de la máquina:

Parámetros de la máquina:

Marking range | 90×150/90×180 mm | ||||

Velocidad de marcado | 1-180 characters/s | ||||

Marking content | Number, character, common symbols, all kinds of graphic, | ||||

Equipment power | 300w | ||||

Air pressure rate | >0.25MPa | ||||

Impact force | 0-25kg | ||||

Impact frequency | 300Hz | ||||

Tamaño del paquete y peso bruto | 42*42*94cm 62kg | ||||

Pneumatic Dot Peen Marking Machine Configurations

| |||||

NO | NAME | MAIN CONFIGURATION | QUANTITY | REMARKS | |

1 | Control Box | Micro stepping driver | 1 set | ||

Photo electriccontrol board | |||||

Transformer | |||||

2 | Mark head | PE linear guide | 1 set | 90×150/90×180 mm | |

Tooth belt | |||||

Solenoid valve | |||||

Stepping motor | |||||

3 | Software | Mark software | 1set | ||

4 | Electric cable | 19 core cable | 1pc | ||

Communication cable | 1set | ||||

Remote control switch | 1pcs | ||||

5 | Pneumatic accessories | 1set | |||

Video Tutorials & Instructional Video:

Pantalla de muestra:

1. Automotive Industry

VIN Marking: Used for marking Vehicle Identification Numbers (VIN) on car chassis and engine blocks, which are essential for tracking and legal identification.

Part Identification: Marks serial numbers, batch numbers, and manufacturer logos on automotive components such as gears, exhaust systems, and engine parts for traceability and quality control.

Engine Components: Essential for marking critical components like pistons, crankshafts, and other engine parts with technical specifications or identification codes.

2. Aerospace Industry

Aircraft Parts Traceability: Used for marking critical aerospace components, such as landing gear, engine parts, and structural components, with serial numbers and tracking information.

Compliance with Standards: Ensures traceability and compliance with aerospace regulations by marking part numbers, maintenance schedules, and other essential information on aircraft parts.

Metal Identification: Provides permanent markings that resist wear and corrosion, making it ideal for components that undergo high stress and harsh environments.

3. Oil and Gas Industry

Pipeline Marking: Marks serial numbers, batch codes, and material specifications on metal pipes, valves, and fittings used in the oil and gas industry, ensuring traceability and safety.

Drilling Equipment: Used for marking heavy-duty components like drill bits, pipe connectors, and other tools that are subject to extreme conditions and need durable, permanent identification.

4. Metal Fabrication

Product Serialization: Marks serial numbers, production dates, and manufacturer logos on metal fabricated parts such as steel sheets, tubes, and frames.

Welding Marking: Often used to mark welding joints or other areas of metal parts to ensure quality control, traceability, and regulatory compliance.

Heavy Metal Structures: Suitable for marking large metal plates and structural components used in construction, infrastructure, and heavy equipment manufacturing.

5. Medical Devices

Surgical Instruments: Marks surgical instruments, medical tools, and implants with serial numbers, lot numbers, and manufacturer details to ensure traceability, sterilization tracking, and compliance with medical regulations.

Implants: Used for marking medical implants, such as titanium plates or screws, with identification marks that ensure traceability throughout the supply chain and during medical procedures.

6. Electrical and Electronics Industry

Component Marking: Marks electrical components, such as switches, relays, and enclosures, with part numbers, serial numbers, and safety certifications.

Panel Marking: Marks control panels, metal enclosures, and housings with identification data, safety information, and branding, ensuring compliance with electrical safety standards.

7. Jewelry and Small Metal Goods

Jewelry Engraving: Ideal for marking serial numbers, brand logos, or custom designs on metal jewelry pieces such as rings, bracelets, and necklaces.

Promotional Items: Used to mark small metal items, including keychains, medals, or souvenirs, with logos, text, or QR codes for branding and customization.

8. Tool and Die Industry

Tool Identification: Used to mark tools, dies, and molds with identification numbers or manufacturer logos to ensure they are traceable and easy to identify in workshop settings.

Die Stamping: Marks die components with production and identification data, ensuring they are easily identifiable during manufacturing.

9. Heavy Equipment and Machinery

Machinery Parts: Used for marking large or heavy machinery components such as hydraulic systems, engines, and structural parts with identification numbers or maintenance schedules.

Construction Equipment: Marks construction tools, bulldozers, cranes, and other heavy equipment with serial numbers or safety information for asset tracking and compliance.

10. Defense and Military

Weapon Marking: Marks firearms, ammunition, and military equipment with serial numbers, manufacturer details, and other identification marks for legal compliance and traceability.

Part Identification: Used for marking parts in military vehicles, aircraft, and weaponry, ensuring traceability and adherence to military standards.

11. Shipbuilding and Marine Applications

Hull Marking: Marks serial numbers and regulatory information on ship hulls and large metal components used in shipbuilding, ensuring compliance with maritime regulations.

Marine Parts: Used for marking parts in marine environments where corrosion-resistant, durable marking is necessary, such as propellers, engines, and structural components.

12. Railway and Transportation

Rail Components: Marks railway components like axles, wheels, and rail tracks with identification numbers, manufacturing dates, and batch codes for traceability.

Vehicle Identification: Marks transportation vehicles and large components with VIN numbers, part numbers, and safety information, ensuring compliance with transportation regulations.

13. Energy and Power Generation

Wind Turbine Components: Used for marking large components in wind turbines and other energy generation equipment, such as serial numbers and part specifications, for maintenance and asset tracking.

Power Plant Equipment: Marks equipment used in power plants, including turbines, generators, and valves, with identification data that ensures traceability and regulatory compliance.

14. Metal Nameplates and Labels

Identification Tags: Marks metal nameplates used for identifying machinery, electrical equipment, and industrial assets with serial numbers, batch codes, and regulatory information.

Compliance Plates: Used to mark compliance and certification information on metal nameplates that are attached to equipment or machinery for safety purposes.

15. Logistics and Asset Management

Asset Tags: Marks metal tags or parts used for asset tracking and inventory management, ensuring that assets can be easily identified and traced throughout their lifecycle.

Inventory Control: Marks equipment, tools, or metal components with barcodes, serial numbers, or QR codes, aiding in logistics and asset management.

Cómo jugar Orden:

- ¿Podría por favor informarnos la siguiente información?

- ¿Qué material vas a marcar?

- ¿Cuál es su área máxima de marcado?

- ¿Necesita profundidad de marcado? ¿O simplemente requiere marcar claramente?

- Nos gustaría recomendarle una máquina de marcado láser adecuada y ofrecerle nuestro mejor precio.

- ¿Enviará la máquina por mar, por aire o por mensajería? Entonces, díganos su puerto marítimo, puerto aéreo o dirección detallada más cercana. Nos gustaría comprobar la tarifa de flete para usted.

- Después de confirmar el modelo de la máquina, la potencia, el precio, la tarifa de flete, infórmenos su Información del destinatario (nombre de la empresa, dirección, contacto, número de teléfono) Nosotros lo harémos Factura de proforma para que juegues orden.

- Puede remitir el pago de acuerdo con la factura proforma.

- La máquina estará lista 10-12 días hábiles después de su pago.

- Compartiremos con usted fotos y videos de la máquina ya que la máquina está lista.

- Después de confirmar que todo está bien, reservaremos el envío.

- Compartiremos con usted conocimiento de embarque, factura comercial, lista de empaque después del envío.

- Puede operar la máquina de marcado láser de acuerdo con el video del usuario y el manual del usuario.

- Si tiene alguna pregunta sobre el uso, nos gustaría guiarlo en línea.

CN

CN Arkansas

Arkansas ES

ES RU

RU