Why Should I Purchase A Fiber Laser Marking Machine?

Why a Fiber Laser Marking Machine is Best for Your Business?

The use of laser marking has increased over the past two decades, mainly due to its popularity as a labeling medium. Its use carries substantive advantages in identifying product inventories and the ability to provide consumer information on products. The wide range of materials that can be marked using this method also makes it extremely flexible for commercial and industrial purposes. For optimal results, choose a máquina de marcado láser de fibra for your business.

How Does Laser Marking Work?

- Laser engraving

- Ablation or removal of a layer of the material

- Carbon migration or etching of the surface of the material to change the color

- Bonding

You can use fiber laser marking on a wide range of materials, from different types of metal through to leather and plastics. Types of metals that lend themselves well to fiber laser engraving include platinum, stainless steel, silver, gold and bronze. Carbide, tungsten, copper, aluminum or medical-grade alloys also respond well to fiber laser marking.

Ways to Use Laser Marking

Medical Devices and Equipment – surgical devices and other medical products that require frequent sterilization (often at high temperatures) use identification marks that can withstand the cleansing process without interfering with the health of the patient.

Jewelry Engraving – creation of unique marks to identify or brand items of jewelry has become popular for copyright protection and recovery of stolen property. The precision of laser engraving is also used to personalize pieces such as wedding bands with the vows or the couple’s marriage date.

Computerized parts such as printed circuit boards use laser marking to produce clear, high-resolution images that are ink- and acid-free for use in electronic applications.

Advantages of Fiber Laser Marking

Fiber laser marking technology has a number of advantages over other types of laser marking systems. The equipment is simpler and cheaper to use than other forms, due in part to the minimal maintenance required and the elimination of any consumables. There are a range of different types of laser marking and engraving machines available, including:

- Fiber (Ytterbaum) 1070 nm

- CO2 (gas laser)

- YAG Flash Lamp (solid state)

- YAG Diode Pumped

- Vanadate

One of the benefits of using fiber markers is minimal part replacement – the diodes have a significant lifespan so there’s no need to budget extensively for parts. When they need replacement, it can be done in the field without requiring a qualified technician to perform any laser alignment.

Then there’s the convenience. The air-cooled design is more convenient than models that use water for cooling purposes, and the quality of the laser beam is better than most of the other types of laser marking machines available. And in terms of space requirements, the equipment has an exceptionally small footprint, which means you can place it in almost any location and operate it without using precious space. This makes it much easier to integrate into an assembly line, or a small factory or workshop without reconfiguring your entire production facility. Overall, fiber laser marking technology is vastly more convenient and cost-effective than other types of marking and engraving machines.

Bienvenido, contáctenos para más detalles.

- Correo electrónico: info@jncslaser.com

- WhatsApp: 0086 18254116182

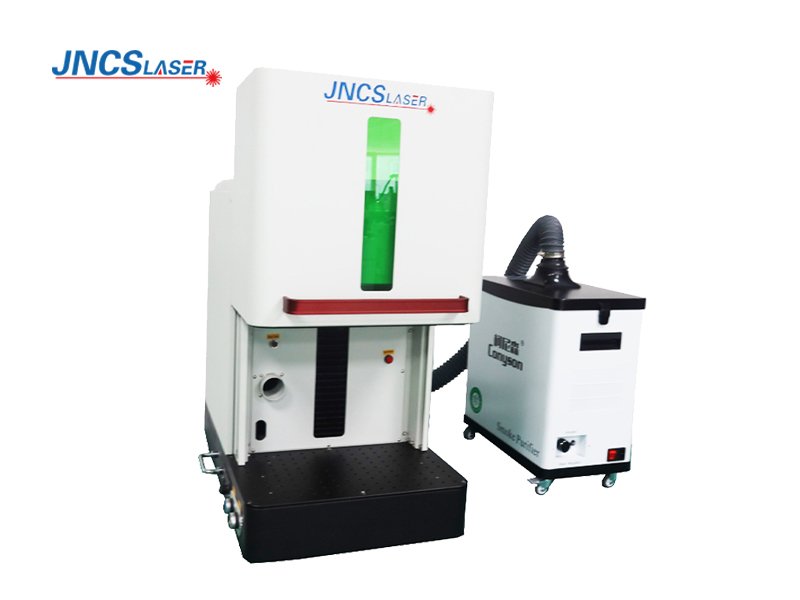

Mini. Máquina de marcado láser de fibra para gabinetes

Fiber Laser Marking Machine Machine with CCD automatic visual and positioning system

Working Video

Working Video

CN

CN Arkansas

Arkansas ES

ES RU

RU