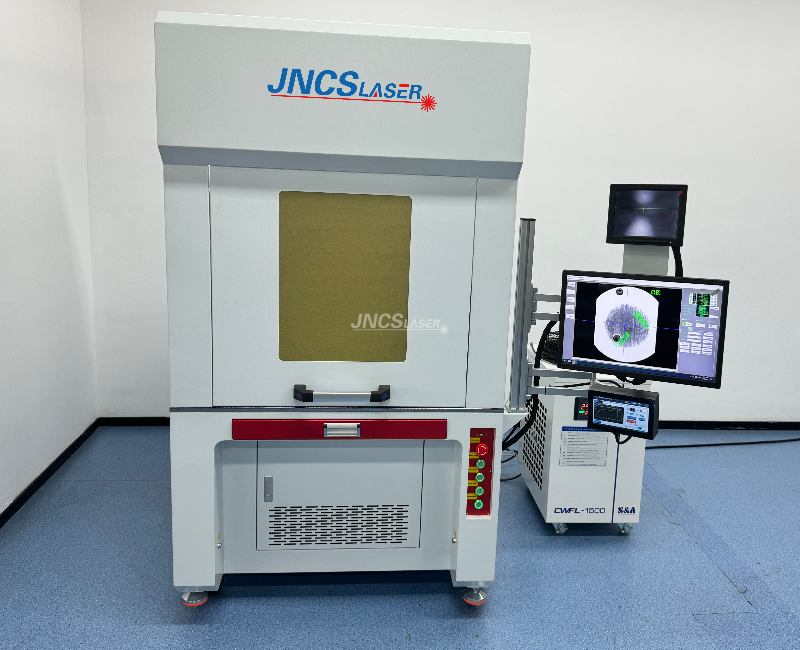

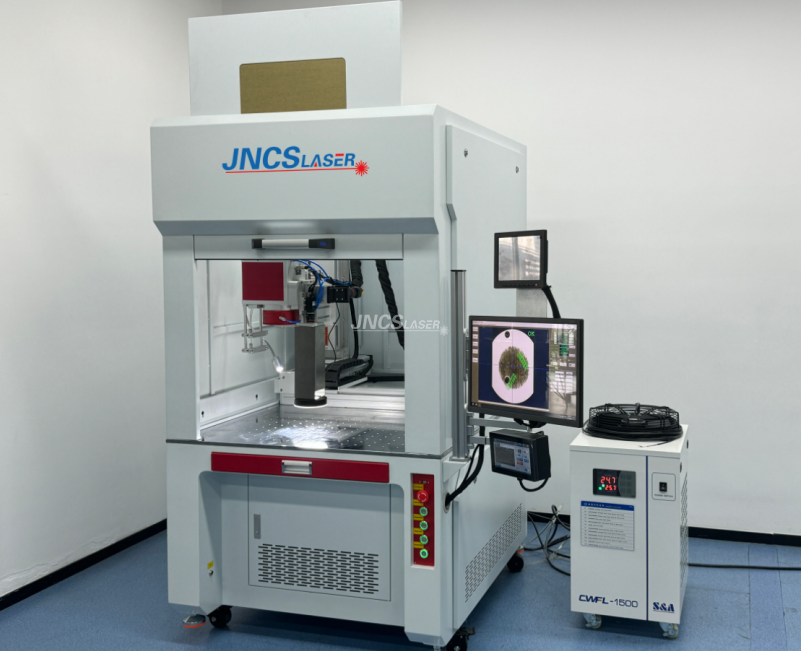

QCW300W Galvanometer Fiber Laser Welding Machine with Visual Positioning System

QCW300W Galvanometer Fiber Laser Welding Machine with Visual Positioning System

1.A set of QCW300W Pulsed fiber laser

2.500X300X300mm traveling size

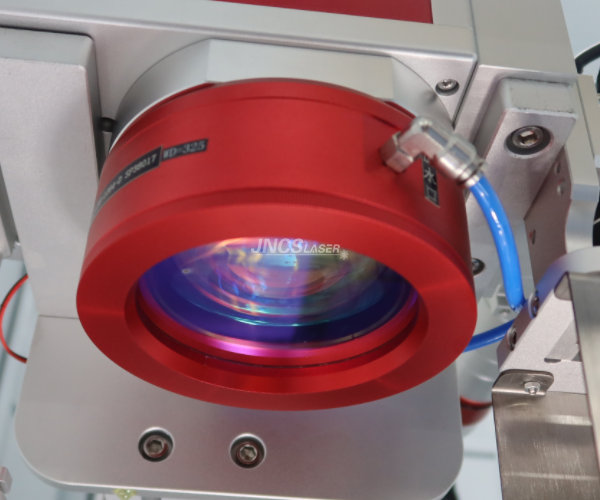

3.A set of galvanometer scanner welding heads;

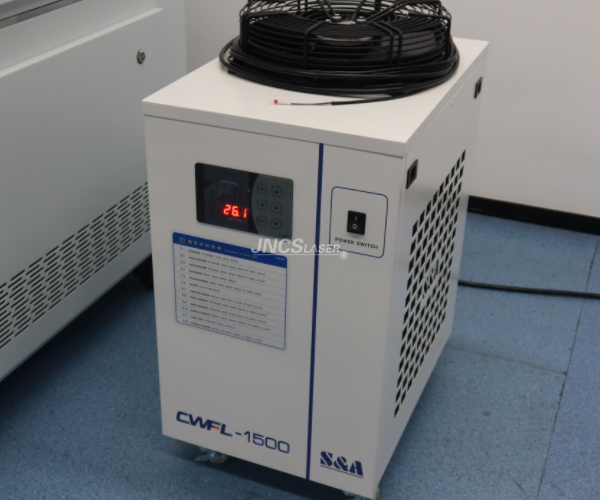

4.One industrial chiller;

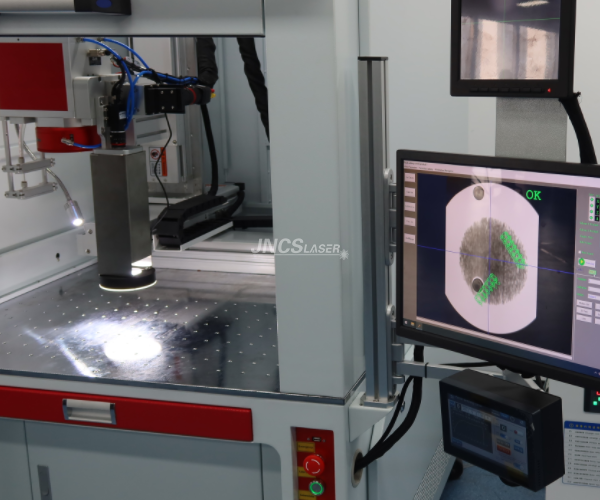

5. A set of computer welding systems;

6.a set of visual positioning system

7.a set of host cabinets.

الميزة الأساسية:

The QCW300W Galvanometer Fiber Laser Welding Machine with a Visual Positioning System is a highly advanced, precision welding solution designed for a wide range of industrial applications. This machine integrates the power and versatility of a 300W fiber laser with the accuracy of galvanometer scanning mirrors and the added advantage of real-time visual positioning. It is ideal for tasks that require high precision, speed, and the ability to work on complex, intricate parts

تكوينات الآلة:

Guangdong Leading Opto-Electronic fiber laser source QCW300W High precision, high quality

With double galvanometer structure, it can perform point, straight line, circle, and other pattern welding output, and complete the welding of various needs. The welding seam is beautiful and the efficiency is very high.

It can detect sample and automatic positioning. We can set welding parameters through the CCD software.

High configuration digital display water chiller, Good cooling effect, good heat dissipation

F254 175X175mm field lens, Machine can weld within this working area. The bigger the size, the weaker the laser power.

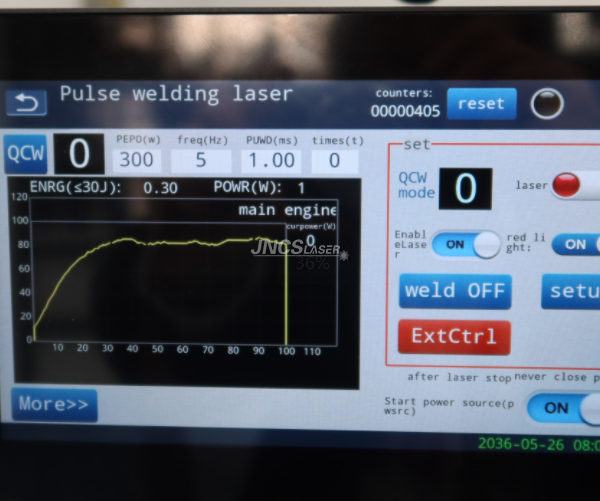

we can set laser power, frequency, pulsed width on this panel.

معلمات الآلة:

نموذج | CS-FL300W |

تصنيف قوة الليزر | 300 واط |

laser device | Pulsed fiber laser |

طاقة الليزر | 300 واط |

Laser type | Fiber laser Quasi-Continuous Wave |

The laser wavelength, | 1064 نانومتر |

Movement patterns | Fiber laser Quasi-Continuous Wave |

Maximum regulation frequency | 1-30Hz |

عرض النبض | 1-20Ms |

Light spot adjustment range | 0.2-5mm (300W) |

Aiming and positioning | CCD Display |

Fiber line length | 10m |

Chiller cooling power | 0.4p |

Rated Power | 3kw |

Cooling way | تبريد الماء |

الطلب على الكهرباء | AC220V 1 phase 50HZ 60A |

Package size and gross weight: | Machine: 146*126*208cm 600KG Water chiller:70*55*105cm 65KG |

Video Tutorials & Instructional Video:

عرض العينة:

تطبيق الجهاز:

Precision Electronics Welding

- Microelectronics, semiconductors, and PCB welding: The QCW300W laser welding machine is ideal for delicate electronic components, such as IC chips, connectors, circuit boards, and electrical components.

- Battery welding: Perfect for precise welding of battery tabs in portable devices like smartphones, laptops, and electric vehicles.

Jewelry and Watch Manufacturing

- Jewelry welding: Used for welding precious metals such as gold, فضة, and platinum to repair jewelry or add intricate designs.

- Watch case welding: The laser’s fine precision allows for seamless welding of watch cases و bands without damaging the surrounding materials.

Medical Device Manufacturing

- Medical implants: The high precision of the QCW300W laser allows for welding medical-grade stainless steel or التيتانيوم components, often used in surgical instruments, implants, or prosthetics.

- Micro-welding of medical devices: The system is capable of welding micro-sized parts with incredible accuracy, critical in medical device manufacturing.

Aerospace & Automotive

- Precision welding of components: Suitable for aerospace parts such as turbine blades, aircraft components, and automotive components where high strength و low distortion are required.

- Exhaust systems, fuel lines, and brake systems in the automotive industry.

Tool and Die Repair

- The system is ideal for mold repairs و tool restoration. The visual positioning system helps ensure that the laser targets only the damaged or worn areas of molds, reducing the need for extensive mold replacement.

Micro- and Nano-Scale Welding

- The fine spot size و accurate beam positioning make this machine ideal for applications in the micro-manufacturing field, such as optics, semiconductors, and high-precision assemblies.

Battery Pack Welding

- The system is widely used in the electric vehicle و battery industry for battery pack assembly, including welding battery tabs to battery cells with high precision.

ترتيب كيفية اللعب:

- هل يمكنك إبلاغنا بالمعلومات أدناه؟

- ما هي المواد التي سوف لحامها؟ سالفولاذ المقاوم للصدأ والحديد والكربون الصلب والألمنيوم والصفائح المجلفنة؟

- ما هي سماكة اللحام لكل نوع من المعادن؟

- نود أن نوصيك بقدرة لحام ليزر مناسبة 1kw 1.5kw 2kw وفقًا لذلك ونقدم لك أفضل سعر لدينا.

- هل ستشحن الآلة عن طريق البحر ، عن طريق الجو؟ لذا ، من فضلك قل لنا أقرب ميناء بحري لك. نود التحقق من رسوم الشحن بالنسبة لك.

- بعد تأكيد طراز الماكينة ، الطاقة ، السعر ، رسوم الشحن ، يرجى إبلاغنا معلومات المرسل إليه (اسم الشركة ، العنوان ، جهة الاتصال ، رقم الهاتف) سنقوم الفاتورة الأولية لتلعب النظام.

- يمكنك تحويل الدفعة وفقًا للفاتورة الأولية.

- ستكون الآلة جاهزة خلال 10-12 يوم عمل بعد الدفع.

- سنشارك معك الصور ومقاطع الفيديو الآلية نظرًا لأن الجهاز جاهز.

- بعد التأكيد على أن كل شيء على ما يرام ، سنقوم بحجز الشحنة.

- سنطلعك على بوليصة الشحن والفاتورة التجارية وقائمة التعبئة بعد الشحن.

- يمكنك تشغيل آلة اللحام بالليزر وفقًا لفيديو المستخدم ودليل المستخدم.

- إذا كانت لديك أي أسئلة حول الاستخدام ، فنحن نرغب في إرشادك عبر الإنترنت.

CN

CN AR

AR ES

ES RU

RU