Luggage Style Pulse Fiber Laser Cleaning Machine 200W 300W 500W application

The Luggage Style Pulse Fiber Laser Cleaning Machine, available in 200W, 300W, and 500W configurations, offers versatile and efficient cleaning solutions across various industries. Here’s a detailed breakdown of their applications and key features:

1. 200W Model: Balanced Precision and Efficiency

The 200W model excels in medium-duty cleaning tasks where both speed and accuracy are critical. It is widely used for:

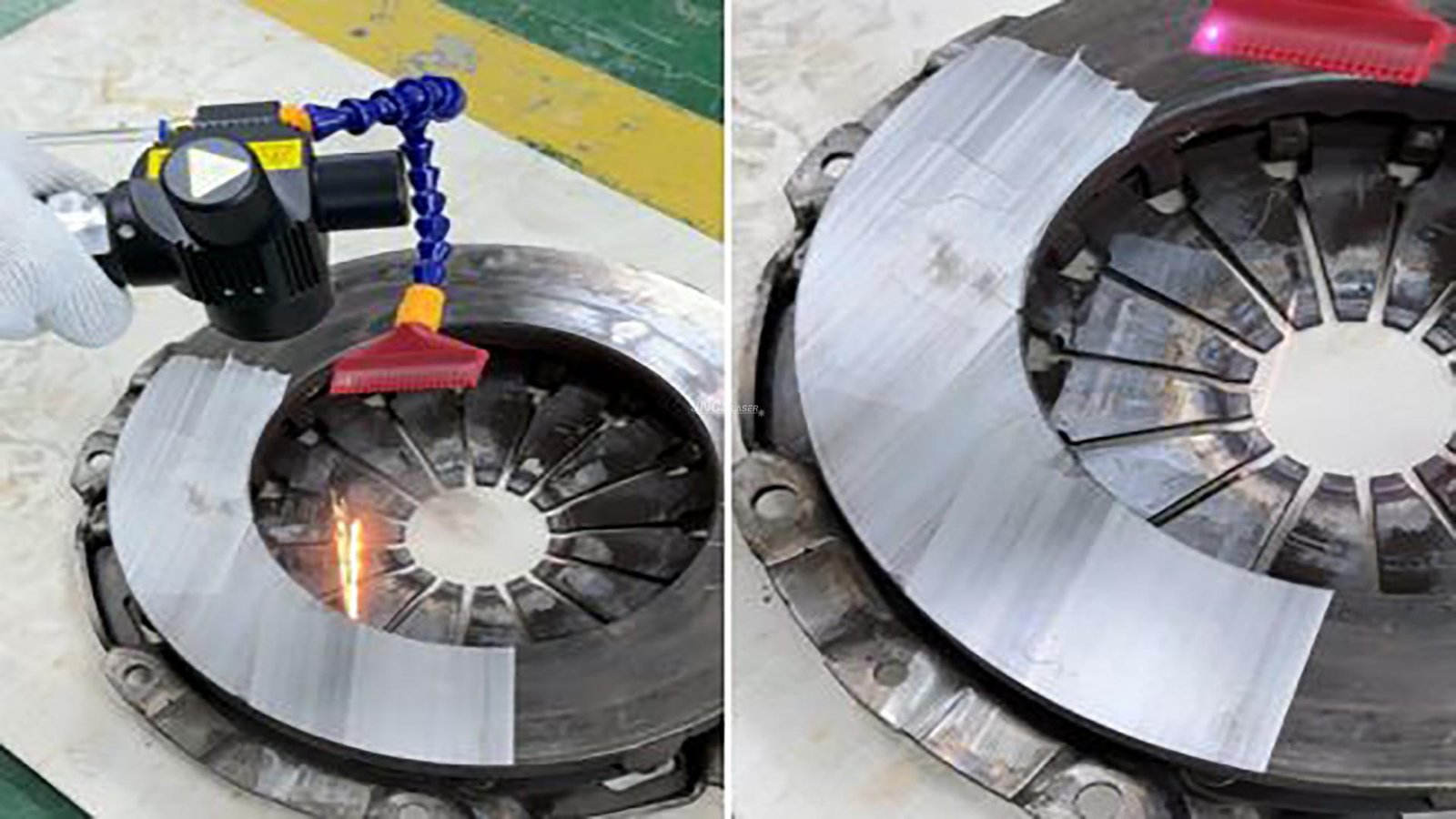

Automotive Manufacturing: Pre-welding surface preparation of car body parts, removal of rust and oil from brake components, and cleaning engine parts without damaging delicate surfaces.

Mold Maintenance: Cleaning tire molds, food processing molds, and electronic component molds by efficiently removing residues and coatings while preserving mold precision.

Cultural Heritage Restoration: Gentle removal of dirt, oxidation, and old paint from artifacts (e.g., metal sculptures, historical machinery) with minimal substrate damage.

General Metal Cleaning: Rust, oil, and thin paint layers on stainless steel, aluminum, or galvanized sheets in small to medium-scale industrial settings.

Technical Highlights:

Air-cooled design ensures portability (net weight ~39 kg) and low maintenance.

9 cleaning modes(e.g., spiral, sinusoidal) allow customization for different workpiece shapes and contamination levels.

Red light-assisted focusing simplifies operation and enhances precision.

2. 300W Model: Enhanced Power for Heavy-Duty Tasks

With increased power, the 300W model tackles thicker contaminants and larger surfaces:

Industrial Equipment Cleaning: Removing thick rust, heavy oil, and epoxy coatings from machinery, pipelines, and structural steel in factories or construction sites.

Aerospace Maintenance: Cleaning aircraft engine components (e.g., turbine blades) and removing old paint from aluminum alloy fuselage sections without compromising material integrity.

Railway Applications: Pre-welding cleaning of railway tracks and removing corrosion from locomotive parts, ensuring safe and efficient rail operations.

Shipbuilding: Stripping paint and rust from ship hulls or marine equipment, offering a eco-friendly alternative to chemical solvents.

Technical Highlights:

Higher pulse energy (up to 12.5 mJ) and frequency (1–3000 kHz) enable faster material removal.

Extended fiber cable length (10m) provides flexibility for hard-to-reach areas.

Wider scanning range (0–145 mm) suits large-scale cleaning projects.

3. 500W Model: High-Power for Extreme Contamination

The 500W model is engineered for industrial-scale cleaning of heavily corroded or coated surfaces:

Foundries and Shipyards: Efficiently stripping thick paint, rust, and oxide layers from cast iron, steel plates, and ship decks. It achieves cleaning speeds of 10–20 m²/h, far exceeding traditional methods.

Rail Transit: Layered paint removal from high-speed rail carriages and cleaning aluminum/titanium alloy components during manufacturing or maintenance.

Energy Sector: Cleaning offshore wind turbine parts, power plant equipment, and oil rig structures exposed to harsh environments.

Metal Processing: Preparing steel coils or sheets for coating by removing mill scale and contaminants, improving adhesion quality.

Technical Highlights:

Ultra-high power density ensures deep penetration and rapid material ablation.

Integrated water cooling maintains stability during continuous operation. Sa3.0 cleanliness standard guarantees near-perfect surface preparation for critical applications like welding or painting.

Common Applications Across All Models

Electronics: Cleaning PCB solder residues and oxide layers on connectors.

Food & Pharmaceutical: Sterilizing molds and equipment without chemical residues.

Art & Architecture: Restoring metal statues, graffiti removal from walls, and cleaning historical metalwork.

Key Advantages

Portability: Luggage-style design (e.g., 28 kg for 200W) allows easy transport to job sites, even on high-speed trains.

Eco-Friendly: No chemicals, minimal waste, and low energy consumption (e.g., 500W model uses ≤2 kW/h).

Non-Destructive: Precise control prevents substrate damage, making it ideal for delicate or high-value materials.

Cost-Effective: Reduced labor and maintenance costs compared to sandblasting or chemical cleaning, with ROI typically achieved within 2–3 years.

Model Selection Guide

200W: Ideal for small to medium tasks requiring precision (e.g., mold cleaning, automotive parts).

300 واط: Best for industrial applications with moderate contamination (e.g., railway tracks, aerospace components).

500 واط: Optimal for large-scale, heavy-duty projects (e.g., shipyards, foundries).

For tailored recommendations, consider factors like material type, contamination thickness, and required throughput. Manufacturers often provide free sample testing to validate performance for specific use cases.

Luggage Style Pulsed Fiber Laser Cleaning Machine Video:

يرجى الاتصال بنا للحصول على مزيد من التفاصيل:

حقوق الطبع والنشر تنتمي إلى JNCSLASER

بريد الالكتروني: info@jncslaser.com

Whatsapp/Wechat: 0086 18254116182

CN

CN AR

AR ES

ES RU

RU