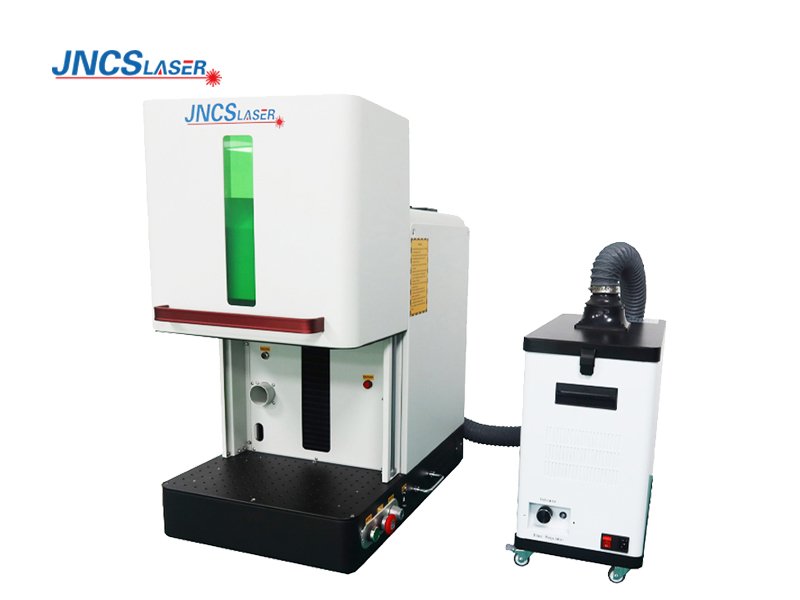

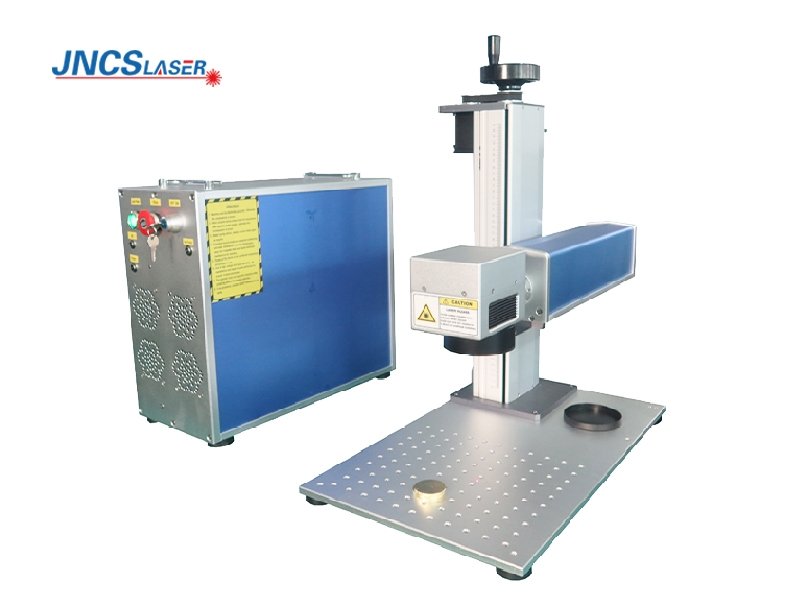

50W 100W fiber laser marking machine for cutting silver, gold, jewelry letters cutting machine

50w 60w 100w fiber laser marking machine for jewelry letter cutting application

Fiber laser marking machines with 50W, 60W, and 100W power outputs are highly effective for cutting letters and intricate designs in jewelry due to their precision, speed, and versatility. Here’s an overview of the features, benefits, and applications of these machines for jewelry letter cutting:

Key Features:

High Precision:

- Fiber lasers produce a finely focused beam that allows for extremely precise cutting of small, intricate designs and letters in jewelry.

Adjustable Power Levels:

Power levels can be adjusted to suit different materials and thicknesses, providing flexibility for various jewelry designs.

Clean Cuts:

Produces clean, smooth cuts with minimal burring or rough edges, often eliminating the need for secondary finishing.

Non-Contact Process:

The non-contact nature of laser cutting reduces the risk of damage or deformation to delicate jewelry pieces.

High Speed:

Capable of cutting at high speeds, improving productivity and reducing processing time.

Automated and Computer-Controlled:

CNC technology allows for precise control over the cutting process, ensuring consistent quality and the ability to handle complex geometries.

Benefits:

Versatility:

Suitable for a wide range of materials used in jewelry, including gold, silver, platinum, titanium, stainless steel, and other metals.

Customization:

Ideal for creating custom designs, monograms, and personalized engravings, catering to the demand for unique and bespoke jewelry pieces.

Efficiency:

High-speed operation and automation enhance productivity, allowing for efficient batch production of jewelry pieces.

Minimal Waste:

Precision cutting minimizes material waste, optimizing the use of precious metals and other materials.

Enhanced Design Capabilities:

Ability to cut intricate patterns and detailed designs opens up new possibilities for innovative jewelry creations.

Applications:

Letter Cutting:

Personalized Jewelry: Cutting initials, names, and custom messages on rings, pendants, bracelets, and other jewelry items.

Monograms: Creating intricate monogram designs for personalized and bespoke jewelry pieces.

Intricate Designs:

Filigree Work: Producing delicate filigree patterns and openwork designs with high precision.

Patterns and Motifs: Cutting complex patterns and motifs on jewelry surfaces for decorative purposes.

Custom Shapes:

Charms and Pendants: Creating custom-shaped charms and pendants with precise details and clean edges.

Earring Designs: Cutting intricate earring designs, including hoops, studs, and dangles.

Engraving:

Deep Engraving: Performing deep engraving on jewelry surfaces to create relief patterns and textured designs.

Surface Marking: Adding detailed surface markings and engravings for decorative and informational purposes.

Prototyping:

Dهsign Prototyping: Creating prototypes of new jewelry designs to evaluate aesthetics and functionality before mass production.

Custom Orders: Producing one-off custom orders with specific design requirements.

Production Efficiency:

Batch Production: Efficiently producing multiple pieces of jewelry with consistent quality and precision.

High Volume: Handling high-volume production runs for commercial jewelry manufacturing.

Summary:

Fiber laser marking machines with 50W, 60W, and 100W power outputs are well-suited for cutting letters and intricate designs in jewelry. Their precision, speed, and versatility make them ideal for creating personalized and custom jewelry pieces, intricate patterns, and detailed engravings. These machines offer significant benefits in terms of efficiency, minimal material waste, and enhanced design capabilities, making them valuable tools for both small-scale artisans and large-scale jewelry manufacturers.

Fiber Laser Marking Machine Video:

يرجى الاتصال بنا للحصول على مزيد من التفاصيل:

حقوق الطبع والنشر تنتمي إلى JNCSLASER

بريد الالكتروني: info@jncslaser.com

Whatsapp/Wechat: 0086 18254116182

CN

CN AR

AR ES

ES RU

RU