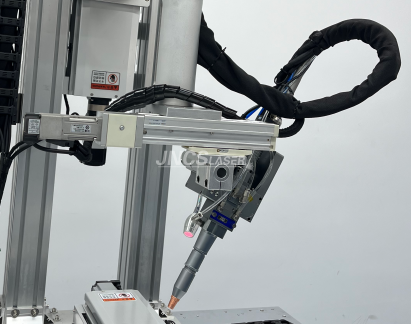

5 Axis Platform Automatic Continuous Fiber Laser Welding Machine with Rotating Head

الميزة الأساسية:

- Laser welding is a new type of welding method and one of the important aspects of the application of laser material processing technology. Laser welding is to radiate a laser beam to the processed object. After heating the surface of the workpiece, the surface heat diffuses into the interior through heat conduction. By controlling the parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool. , After cooling to form a weld. The welding process is of thermal conductivity type, and the advantages are large aspect ratio, fast welding speed, small thermal influence range, and small workpiece deformation.

Its main technical characteristics: - The control system is a professional four-axis control system tailored for laser welding. It has powerful PC control and is easy to program,debug and maintain. It can complete automatic or semi-automatic spot welding, butt welding, stitch welding, and sealing welding. Welding of plane straight lines, arcs and arbitrary trajectories; the system is simple and reliable to operate, easy to control, simple to operate, easy to learn, easy to understand and easy to use for users;

- Equipped with three-axis automatic worktable, super large worktable, platform XY dual-axis electric module, Z-axis adopts power-off brake motor, and can be equipped with rotating shaft when it is time. For special-shaped three-dimensional products, it can realize three-dimensional laser welding, fast speed, long life accuracy high;

Customized automated tooling fixtures can be combined with assembly lines,photoelectric sensors, pneumatic fixtures and other combinations for fully automatic processing to achieve mass production of products. - It can perform time splitting or energy splitting, suitable for applications in different processing occasions, multi-station processing applications, and can be widely used in laser welding such as spot welding, continuous welding and flexible processing industries.

- Support multi-channel optical fiber output to improve welding efficiency, save equipment cost, and reduce equipment occupation space. You can choose multiple optical fiber to output light in time, or to output light at the same time according to the needs, or any combination of the two, so it can be carried out. Multi-beam simultaneous processing and multi-station processing provide conditions for more precise welding;

After the laser passes through the optical fiber, the spot becomes more uniform and stable, which improves the quality of the weld. After the laser beam is focused, a small spot can be obtained, the power density is high, and it can be accurately positioned. It can be applied to the assembly welding of micro and small workpieces in mass automated production.

تكوينات الآلة:

Adopting famous brands (Raycus / JPT/Max. And Germany IPG)

equipped with 1.5p water chiller, it can meet with requirements for a long time, high power welding is more stable.

Display on a video, display by connect the device, clear welding point

High precision, we will install machine software on the computer

laser power, emergency switch, allow light, PC

with rotating function

معلمات الآلة:

|

إسم الألة |

آلة لحام ألياف الليزر الأوتوماتيكية |

|

طاقة الليزر |

1KW 1.5KW 2KW 3KW |

|

Laser type |

fiber-optic laser |

|

طول موجة الليزر |

1080nm ±5nm |

|

Sport mode |

Continuous/modulation |

|

Adjust frequency |

1000HZ |

|

Focus range |

150-250mm Optional |

|

Fiber core diameter |

50-100um |

|

مصدر الليزر |

Raycus / JPT / IPG/Max |

|

Spectroscopic method |

Precision energy spectroscopy or high-speed time spectroscopy |

|

طول الألياف |

10 م |

|

وضع التبريد |

تبريد الماء |

|

Cooling power of chiller |

1.5P |

|

طاقة كهربائية شغالة |

1kw 1.5kw 2kw AC220V / 50Hz / 60HZ 3kw AC380V / 50Hz / 60HZ |

|

حجم العبوة |

Machine:139*139*190cm Chiller: 80*65*117cm |

|

الوزن الإجمالي |

Machine:419kg Chiller: 98kG |

Video Tutorials & Instructional Video:

عرض العينة:

تطبيق الجهاز:

The fiber optic continuous welding machine has a wide range of applications. It is used in the sanitary industry: water pipe joints, reducers, tees, valves, battery industries: lithium batteries, battery packs, laser welding of electrodes, glasses industry: stainless steel, titanium Alloy and other materials for glasses buckle, precise welding of outer frame and other positions, hardware industry: impeller, kettle, water cup, stainless steel bowl, sensor, diode, aluminum alloy, mobile phone battery, door handle, shelf, etc.

ترتيب كيفية اللعب:

- هل يمكنك إبلاغنا بالمعلومات أدناه؟

- ما هي المواد التي سوف لحامها؟ سالفولاذ المقاوم للصدأ والحديد والكربون الصلب والألمنيوم والصفائح المجلفنة؟

- ما هي سماكة اللحام لكل نوع من المعادن؟

- نود أن نوصيك بقدرة لحام ليزر مناسبة 1kw 1.5kw 2kw وفقًا لذلك ونقدم لك أفضل سعر لدينا.

- هل ستشحن الآلة عن طريق البحر ، عن طريق الجو؟ لذا ، من فضلك قل لنا أقرب ميناء بحري لك. نود التحقق من رسوم الشحن بالنسبة لك.

- بعد تأكيد طراز الماكينة ، الطاقة ، السعر ، رسوم الشحن ، يرجى إبلاغنا معلومات المرسل إليه (اسم الشركة ، العنوان ، جهة الاتصال ، رقم الهاتف) سنقوم الفاتورة الأولية لتلعب النظام.

- يمكنك تحويل الدفعة وفقًا للفاتورة الأولية.

- ستكون الآلة جاهزة خلال 10-12 يوم عمل بعد الدفع.

- سنشارك معك الصور ومقاطع الفيديو الآلية نظرًا لأن الجهاز جاهز.

- بعد التأكيد على أن كل شيء على ما يرام ، سنقوم بحجز الشحنة.

- سنطلعك على بوليصة الشحن والفاتورة التجارية وقائمة التعبئة بعد الشحن.

- يمكنك تشغيل آلة اللحام بالليزر وفقًا لفيديو المستخدم ودليل المستخدم.

- إذا كانت لديك أي أسئلة حول الاستخدام ، فنحن نرغب في إرشادك عبر الإنترنت.

CN

CN AR

AR ES

ES RU

RU