Pulsed fiber laser cleaning machine for auto parts restore application

A pulsed fiber laser cleaning machine is an advanced tool used for restoring auto parts by removing rust, paint, coatings, and contaminants without damaging the underlying material. This technology is widely used in the automotive industry for cleaning and restoring components like engine parts, brake discs, chassis, and more. Here’s an overview of how it works and its benefits:

How It Works

1. **Laser Source**: The machine uses a pulsed fiber laser, which emits high-energy laser pulses in short bursts.

2. **Ablation Process**: The laser beam is directed onto the surface of the auto part. The energy from the laser causes contaminants (rust, paint, etc.) to vaporize or turn into dust, while the base material remains unaffected.

3. **Non-Contact Cleaning**: The process is non-contact, meaning there is no physical abrasion or wear on the part being cleaned.

4. **Precision**: The laser can be finely tuned to target specific areas or layers, making it ideal for delicate or complex parts.

Key Features

**Efficient Cleaning**: Removes rust, oil, grease, paint, and other contaminants quickly and effectively.

**Non-Destructive**: Preserves the integrity of the base material (e.g., metal, plastic, or rubber).

**Eco-Friendly**: No chemicals, water, or abrasive materials are used, making it environmentally friendly.

**Automation**: Can be integrated into robotic systems for automated cleaning in production lines.

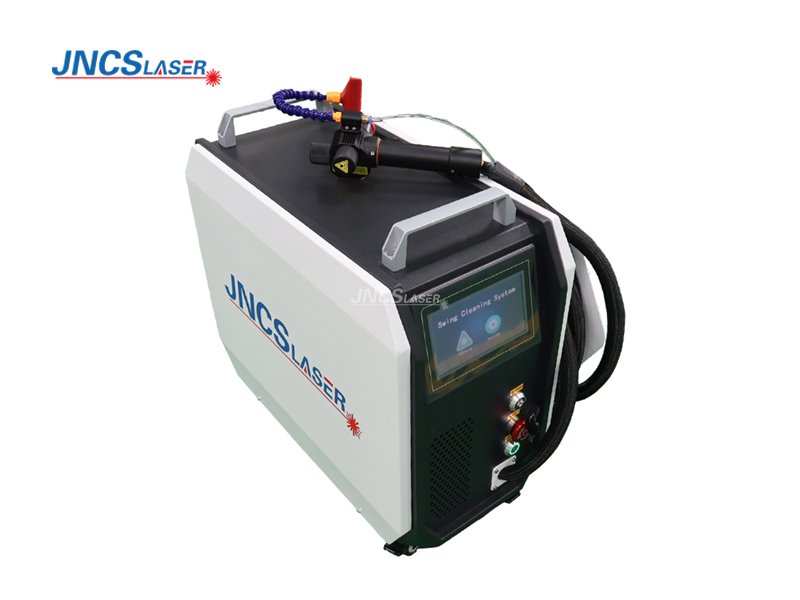

**Portable Options**: Some models are compact and portable for on-site repairs or workshops.

Applications in Auto Parts Restoration

1. **Rust Removal**: Cleans rust from metal surfaces like chassis, suspension components, and exhaust systems.

2. **Paint Stripping**: Removes old paint layers without damaging the metal underneath.

3. **Grease and Oil Removal**: Cleans engine parts, transmission components, and other oily surfaces.

4. **Weld Preparation**: Prepares surfaces by removing oxides and contaminants before welding.

5. **Restoration of Classic Cars**: Ideal for restoring vintage or classic car parts without compromising their original structure.

Advantages Over Traditional Methods

**No Abrasives**: Unlike sandblasting or grinding, there is no risk of damaging the part.

**No Chemicals**: Eliminates the need for harsh chemicals, reducing environmental impact.

**Precision**: Can clean intricate geometries and hard-to-reach areas.

**Cost-Effective**: Reduces waste and labor costs over time.

Considerations When Choosing a Machine

1. **Laser Power**: Higher power (e.g., 100W, 200W, 500W) allows for faster cleaning but may increase costs.

2. **Pulse Frequency**: Adjustable pulse frequencies enable customization for different materials and contaminants.

3. **Portability**: Depending on your needs, choose between stationary or portable models.

4. **Safety Features**: Ensure the machine has proper safety measures, such as protective enclosures and laser safety glasses.

5. **Budget**: Pulsed fiber laser cleaners can be expensive, so consider the return on investment (ROI) based on your usage.

Popular Brands and Models

**IPG Photonics**: Known for high-quality fiber lasers.

**CleanLasers**: Offers portable and industrial laser cleaning systems.

**Laser Photonics**: Provides a range of laser cleaning machines for automotive applications.

**HAN’S LASER**: A leading manufacturer of laser cleaning equipment.

Conclusion

A pulsed fiber laser cleaning machine is a highly effective and versatile tool for auto parts restoration. It offers a clean, precise, and eco-friendly alternative to traditional cleaning methods, making it a valuable investment for automotive workshops, restoration specialists, and manufacturing facilities. If you’re considering purchasing one, evaluate your specific needs and choose a machine with the right power, features, and safety measures.

pulsed fiber laser cleaning machine working video:

Por favor, póngase en contacto con nosotros para más detalles:

Los derechos de autor pertenecen a JNCSLASER

Correo electrónico: info@jncslaser.com

Whatsapp/Wechat: 0086 18254116182

CN

CN Arkansas

Arkansas ES

ES RU

RU