Applications of Fiber Laser Marking Machine with CCD and Conveyor belt

Fiber laser marking machines equipped with a CCD (Charge-Coupled Device) visual positioning system and a conveyor belt offer advanced capabilities for high-precision, automated marking processes. Here are some applications of such a system:

1. Electronics Industry:

- PCB Marking:The CCD visual positioning system ensures accurate alignment for marking circuit boards, even as they move on the conveyor belt. This is crucial for serial numbers, barcodes, and other identifiers.

- Component Marking:Small electronic components like resistors, capacitors, and ICs can be marked with high precision, ensuring traceability and compliance with industry standards.

2. Automotive Industry:

- Part Identification:Automotive parts, including engine components, gears, and sensors, can be marked with serial numbers, QR codes, and other identifiers for traceability.

- Labeling of Plastic and Metal Parts:The system ensures that labels on plastic and metal parts are consistently accurate, improving quality control.

3. Medical Devices:

- Surgical Instruments:Marking surgical instruments with unique identifiers to ensure traceability and compliance with medical regulations.

- Medical Equipment Components:Precise marking of components used in medical devices, such as implants and diagnostic equipment, ensuring high readability and adherence to strict industry standards.

4. Consumer Goods:

- Appliance Marking:Marking of home appliances with brand logos, serial numbers, and other identifiers. The conveyor system allows for continuous production flow.

- Tool and Hardware Identification:Marking hand tools and hardware items with brand names, part numbers, and logos to enhance brand recognition and traceability.

5. Packaging Industry:

- Batch Coding and Expiry Dates:Marking packaging materials with batch codes, manufacturing dates, and expiry dates, ensuring compliance with regulations and improving traceability.

- Branding and Logos:High-speed marking of packaging with brand logos and promotional information as products move along the conveyor.

6. Jewelry and Luxury Goods:

- Engraving:Precision engraving of intricate designs, serial numbers, and logos on jewelry and luxury items. The CCD system ensures that the markings are perfectly aligned.

- Quality Assurance:Automated marking of authenticity codes on luxury items to prevent counterfeiting.

7. Industrial Manufacturing:

- Tool Marking:Marking tools and machine parts with part numbers, manufacturer logos, and other identifiers. This improves inventory management and product traceability.

- Component Marking:High-speed marking of components in a production line, ensuring consistency and accuracy.

8. Aerospace Industry:

- Component Identification:Marking aerospace components with serial numbers, batch codes, and inspection marks to ensure traceability and adherence to safety standards.

- Material Certification:Marking materials with certification marks and other identifiers to ensure compliance with industry regulations.

Advantages of Using CCD Visual Positioning and Conveyor Belt:

- High Precision and Accuracy:The CCD visual positioning system ensures that each item is accurately aligned before marking, reducing errors and improving quality.

- Automation and Efficiency:The conveyor belt system allows for continuous, automated processing of items, increasing throughput and reducing manual labor.

- Flexibility:The system can handle various shapes and sizes of products, making it versatile for different applications and industries.

- Consistency:Ensures consistent marking quality and placement across all items, which is critical for maintaining brand standards and compliance.

- Real-time Adjustment:The CCD system can make real-time adjustments based on the position of the item, ensuring precise marking even if the items are not perfectly aligned on the conveyor.

In summary, a fiber laser marking machine with a CCD visual positioning system and conveyor belt is a highly versatile and efficient solution for high-precision marking in various industries, improving automation, accuracy, and overall productivity.

Bienvenido, contáctenos para más detalles.

- Correo electrónico: info@jncslaser.com

- WhatsApp: 0086 18254116182

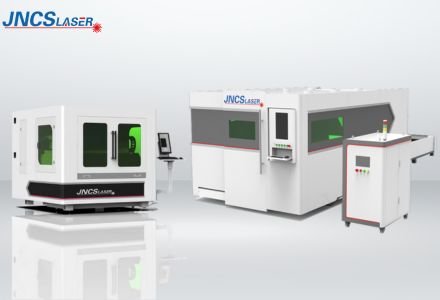

Pantalla de muestra:

Si desea obtener más información al respecto, póngase en contacto con nosotros por correo electrónico o por whatsapp/wechat.

Correo electrónico: info@jncslaser.com

WhatsApp: 0086 18254116182

CN

CN Arkansas

Arkansas ES

ES RU

RU