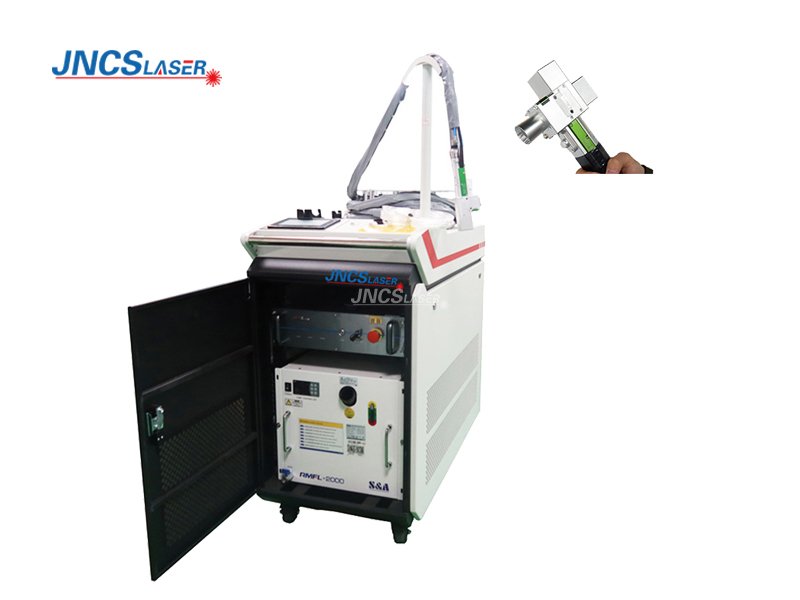

High Quality 200W 300W Pulsed Fiber Laser Cleaning Machine

Pulsed Fiber Laser Cleaning Machine for Rust Paint Oil Removing

تقييم:

Laser cleaning is a new technology based on the interaction of laser and matter, which can achieve the effect of removing contamination and attachments on the surface of objects. Compared with traditional cleaning methods, laser cleaning has the advantages of non-contact, no damage to the substrate, precise cleaning, “green” environmental protection and online availability, and is especially suitable for high-speed online cleaning in designated areas.

الميزة الأساسية:

A pulsed fiber laser cleaning machine is a type of laser cleaning equipment that utilizes pulsed laser technology for efficient and precise cleaning applications. It provides a focused and high-energy laser beam that interacts with the surface contaminants, removing them through various mechanisms such as ablation, vaporization, and shockwave generation. Here are the main features and characteristics of a pulsed fiber laser cleaning machine:

Pulsed Laser Technology: The machine employs a pulsed fiber laser as its energy source. Pulsed lasers emit high-intensity laser pulses with controlled durations and repetition rates. This allows for precise control over the energy delivered to the surface, optimizing the cleaning process.

Versatile Cleaning Capabilities: Pulsed fiber laser cleaning machines can effectively remove a wide range of contaminants, including rust, paint, oxides, grease, oil, coatings, residues, and more. They can be used on various surfaces, including metals, plastics, composites, ceramics, and delicate materials.

High Cleaning Efficiency: The pulsed laser technology used in these machines provides high cleaning efficiency. The intense laser pulses rapidly heat and vaporize the contaminants, causing them to be expelled from the surface. This enables quick and thorough cleaning, even in hard-to-reach areas.

Non-contact and Non-abrasive Cleaning: Pulsed fiber laser cleaning is a non-contact and non-abrasive method. The laser energy removes contaminants without physically touching the surface, minimizing the risk of surface damage or scratches. It eliminates the need for chemical solvents, sandblasting, or mechanical scrubbing, making it a gentle yet effective cleaning solution.

Precise Control and Customization: Pulsed fiber laser cleaning machines offer precise control over various cleaning parameters, such as pulse duration, energy, repetition rate, and scanning patterns. This allows operators to customize the cleaning process according to the specific requirements of the application, ensuring optimal results.

Environmentally Friendly: Pulsed fiber laser cleaning is an environmentally friendly cleaning method. It does not involve the use of chemicals or generate harmful by-products. Additionally, it significantly reduces the generation of waste compared to traditional cleaning methods.

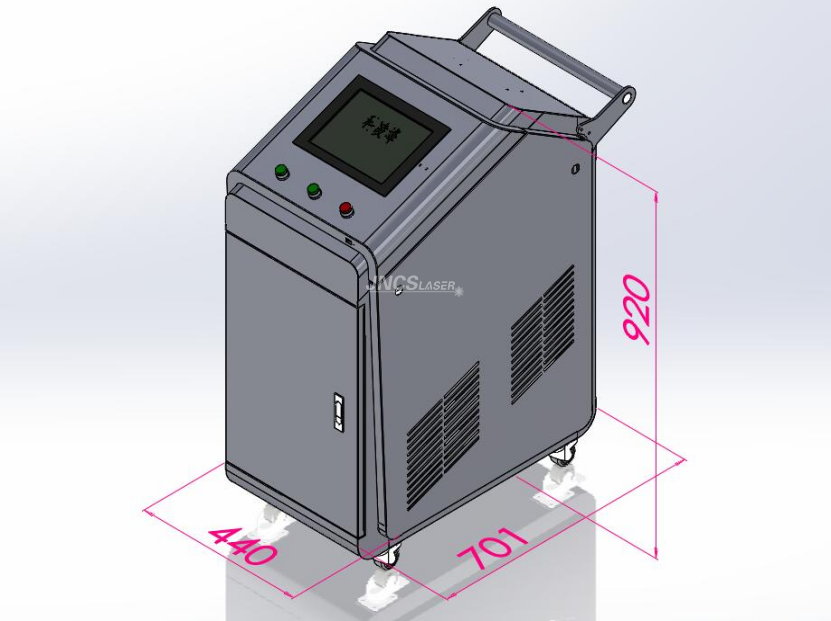

Compact and Portable Design: These machines are designed to be compact and portable, allowing for easy maneuverability and flexibility in various work environments. They can be handheld or mounted on robotic systems, making them suitable for both stationary and mobile cleaning operations.

Pulsed fiber laser cleaning machines are widely used in industries such as automotive, aerospace, electronics, manufacturing, and cultural heritage preservation. They provide a precise, efficient, and eco-friendly solution for a wide range of cleaning applications, enabling improved productivity and quality in surface preparation and maintenance processes.

تكوينات الآلة:

Operational Panel and Controller: The DHCP200 supports eight cleaning modes and is suitable for a variety of complex cleaning scenarios. Support real-time control of laser power slow rise and slow down, better cleaning effect, no damage to the substrate. The DHCP200 supports 15 languages, which can be used by users in more countries.

Handheld Double Axis cleaning Head: Small size, light weight, easy to operate,DHCP200 adopts self-developed high-speed galvanometer motor, and the product structure design is more reasonable and the stability is higher. Compatible with the current market mainstream laser (OCS output), support structure customization. Weight of cleaning head: 850g.

Pulsed Fiber Laser : YDFLP-CL2-200. 200w pulsed fiber laser source, air cooling laser source, it is used for cleaning. This type of fiber laser adopts fiber-coupled output semiconductor laser for pumping, which has higher energy conversion efficiency; and the laser adopts air-cooling system, which makes the heat dissipation structure more compact, smaller and more portable; and the integrated all-fiber design makes the system maintenance-free, which is convenient for customers to use.

معلمات الآلة:

إسم الألة | Handheld Pulsed Fiber Laser Cleaning Machine CS-FLC200W CS-FLC300W |

طاقة الليزر | 200W 300W |

طول موجة الليزر | 1080 نانومتر |

مصدر الليزر | Shenzhen JPT Pulsed fiber laser source air cooling |

طول الألياف | 5M |

وضع التبريد | تبريد الهواء |

تطبيق | Rust cleaning, Surface Paint Cleaning, Oil cleaning, mold cleaning, weld cleaning |

Cleaning Width | F254 : 130X130MM |

سواء المضادة للانعكاس عالية | نعم |

طاقة كهربائية شغالة | AC220V / 50Hz / 60HZ |

Cleaning Speed | <30000mm/s |

cleaning efficiency | 0.08~8m2 / min |

عرض العينة:

تطبيق الجهاز:

تستخدم آلة التنظيف بالليزر المحمولة نبضات ليزر عالية التردد وذات طاقة عالية لإشعاع سطح قطعة العمل ، بحيث يتبخر الزيت السطحي أو الصدأ أو الطلاء أو يتقشر على الفور ، ويزيل بشكل فعال ملحق السطح أو طلاء السطح من مادة التنظيف سرعة عالية ، وذلك لتحقيق تنظيف الجسم. يتميز بعدم وجود ضرر لمصفوفة الجزء ، لا توجد مواد استهلاكية ، توفير الطاقة وحماية البيئة.

Video Tutorials & Instructional Video:

ترتيب كيفية اللعب:

- هل يمكنك إبلاغنا بالمعلومات أدناه؟

ما هي المواد التي سوف تنظف؟ صust، دهان، زيت؟

- نود أن نوصيك بقوة تنظيف ليزر مناسبة 200 واط و 300 واط و 500 واط وفقًا لذلك ونقدم لك أفضل سعر لدينا.

- هل ستشحن الآلة عن طريق البحر ، عن طريق الجو؟ لذا ، من فضلك قل لنا أقرب ميناء بحري لك. نود التحقق من رسوم الشحن بالنسبة لك.

- بعد تأكيد طراز الماكينة ، الطاقة ، السعر ، رسوم الشحن ، يرجى إبلاغنا معلومات المرسل إليه (اسم الشركة ، العنوان ، جهة الاتصال ، رقم الهاتف) سنقوم الفاتورة الأوليةلتلعب النظام.

- يمكنك تحويل الدفعة وفقًا للفاتورة الأولية.

- ستكون الآلة جاهزة خلال 10-12 يوم عمل بعد الدفع.

- سنشارك معك الصور ومقاطع الفيديو الآلية نظرًا لأن الجهاز جاهز.

- بعد التأكيد على أن كل شيء على ما يرام ، سنقوم بحجز الشحنة.

- سنطلعك على بوليصة الشحن والفاتورة التجارية وقائمة التعبئة بعد الشحن.

- يمكنك تشغيل آلة اللحام بالليزر وفقًا لفيديو المستخدم ودليل المستخدم.

- إذا كانت لديك أي أسئلة حول الاستخدام ، فنحن نرغب في إرشادك عبر الإنترنت.

CN

CN AR

AR ES

ES RU

RU