200w 300w pulsed fiber laser cleaning machine using guide

Scope of application

This product can be used to remove attachments or coatings on the surface of objects,including rust,paint, oil stains,coatings,etc.(High-reflective materials need to be tested and verified).It has the advantages of non-contact,no chemical damage,mobility and high efficiency,etc.

المنتج Description

A pulsed fiber laser cleaning machine is a type of laser cleaning equipment that utilizes pulsed laser technology for efficient and precise cleaning applications. It provides a focused and high-energy laser beam that interacts with the surface contaminants, removing them through various mechanisms such as ablation, vaporization, and shock wave generation. Here are the main features and characteristics of a pulsed fiber laser cleaning machine:

Pulsed Laser Technology: The machine employs a pulsed fiber laser as its energy source. Pulsed lasers emit high-intensity laser pulses with controlled durations and repetition rates. This allows for precise control over the energy delivered to the surface, optimizing the cleaning process.

Versatile Cleaning Capabilities: Pulsed fiber laser cleaning machines can effectively remove a wide range of contaminants, including rust, paint, oxides, grease, oil, coatings, residues, and more. They can be used on various surfaces, including metals, plastics, composites, ceramics, and delicate materials.

High Cleaning Efficiency: The pulsed laser technology used in these machines provides high cleaning efficiency. The intense laser pulses rapidly heat and vaporize the contaminants, causing them to be expelled from the surface. This enables quick and thorough cleaning, even in hard-to-reach areas.

Non-contact and Non-abrasive Cleaning: Pulsed fiber laser cleaning is a non-contact and non-abrasive method. The laser energy removes contaminants without physically touching the surface, minimizing the risk of surface damage or scratches. It eliminates the need for chemical solvents, sandblasting, or mechanical scrubbing, making it a gentle yet effective cleaning solution.

Precise Control and Customization: Pulsed fiber laser cleaning machines offer precise control over various cleaning parameters, such as pulse duration, energy, repetition rate, and scanning patterns. This allows operators to customize the cleaning process according to the specific requirements of the application, ensuring optimal results.

Environmentally Friendly: Pulsed fiber laser cleaning is an environmentally friendly cleaning method. It does not involve the use of chemicals or generate harmful by-products. Additionally, it significantly reduces the generation of waste compared to traditional cleaning methods.

Compact and Portable Design: These machines are designed to be compact and portable, allowing for easy maneuverability and flexibility in various work environments. They can be handheld or mounted on robotic systems, making them suitable for both stationary and mobile cleaning operations.

Use instruction

1.Installation and use requirements

1.1 This machine uses a 110V-220V AC power supply.If this requirement is not met,please use the machine with a transformer.

1.2 The minimum bending radius of the integrated cable is 200mm.

1.3 Please keep at least 60cm of space around the machine to ensure good ventilation and to avoid affecting performance due to poor heat dissipation.

1.4 Ensure the air inlet of the machine is clean,and prevent foreign objects or large particles of dust from being sucked into the chassis.

1.5 The operating environment temperature range of the laser cleaning machine is O to 35°℃.If it exceeds this range,it may cause the system to alarm.

2.Operation precautions

2.1 Please check and ensure that the equipment is powered off before installing/removing laser cleaning components and other operations.

2.2 It is recommended to dedust the lens and the cleaning head with clean air or wipe it with a lens cloth after each use to prevent dust or other pollution.Please cover the lens with a protective cover when the cleaning head is not working.

2.3 When transporting or handling,avoid knocking and overturning.

2.4 If the equipment is abnormal,check and troubleshoot in time or contact the after-sales service.Do not operate the machine to avoid unnecessary losses.

Operation process

- Connect one end of the power cord to the power port of the machine,and the other end to the AC power supply, and connect air pipe ( air compressor).

- Turn on the key switchto start the machine, and then push in Laser Power button.

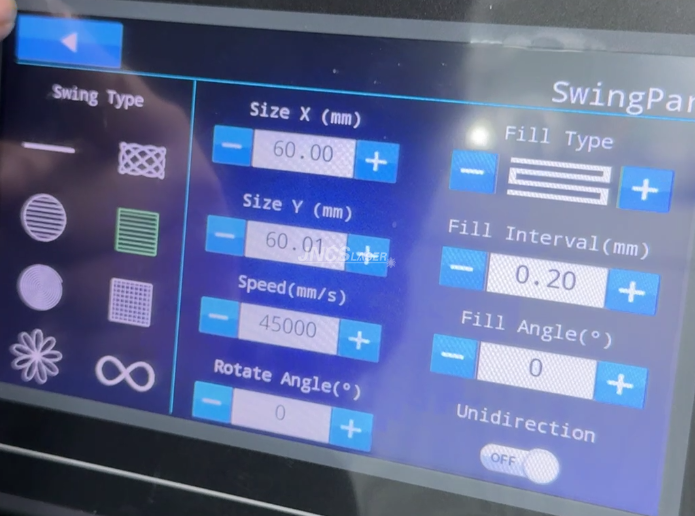

- Set the swingtype and laser parameters according to the target.

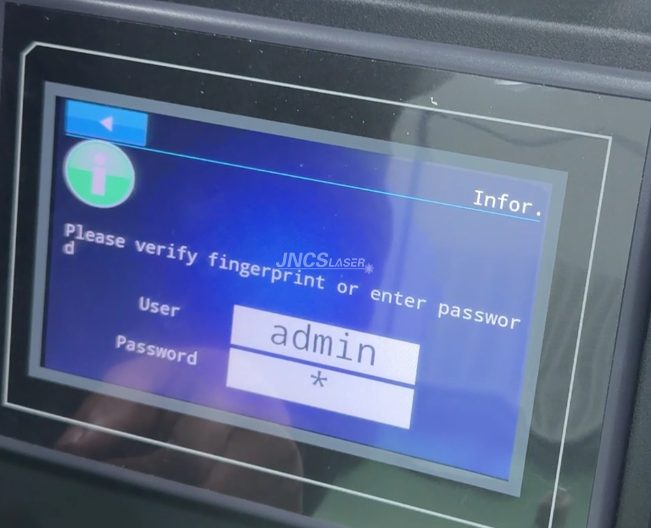

Note: Main page ->System settings ->Default password “6” ->User management ->Set “User type”, “User name”, “Password” and “Fingerprint registration” in order to complete user creation. (The system has established an account: the admin password is the number 1)

Note: Main page ->System settings ->Default password “6” ->User management ->Set “User type”, “User name”, “Password” and “Fingerprint registration” in order to complete user creation. (The system has established an account: the admin password is the number 1)

4. Click”Sway”and “Laser”to enter the cleaning preparation state.  5. Open the protect cover and Double-click the cleaning head button and keep pressing to start cleaning.

5. Open the protect cover and Double-click the cleaning head button and keep pressing to start cleaning.  6. After cleaning,release the button to stop working.

6. After cleaning,release the button to stop working.

Cleaning efficiency for reference 200w 300w 500w 1000w

| Power/W | Material | Cleaning Speed | Cleaning Size | Cleaning Depth | Cleaning Efficiency |

| 200W | Floating Rust | 20mm/s | 130mm | 20um | 6 ㎡/h |

| Oil Paint | 20mm/s | 130mm | 80um | 2.5㎡/h | |

| Rust | 20mm/s | 130mm | 100um | 2㎡/h | |

| 300 واط | Floating Rust | 20mm/s | 100mm | 20um | 9㎡/h |

| Oil Paint | 20mm/s | 100mm | 80um | 4㎡/h | |

| Rust | 20mm/s | 100mm | 100um | 3㎡/h | |

| 500 واط | Floating Rust | 25mm/s | 120mm | 20um | 12㎡/h |

| Oil Paint | 25mm/s | 120mm | 80um | 5㎡/h | |

| Rust | 25mm/s | 120mm | 100um | 3.5㎡/h | |

| 1000 واط | Floating Rust | 30mm/s | 120mm | 20um | 15㎡/h |

| Oil Paint | 30mm/s | 120mm | 80um | 6㎡/h | |

| Rust | 30mm/s | 120mm | 100um | 4㎡/h |

Welcome to contact us for more details.

- بريد الالكتروني: info@jncslaser.com

- ال WhatsApp: 0086 18254116182

CN

CN AR

AR ES

ES RU

RU